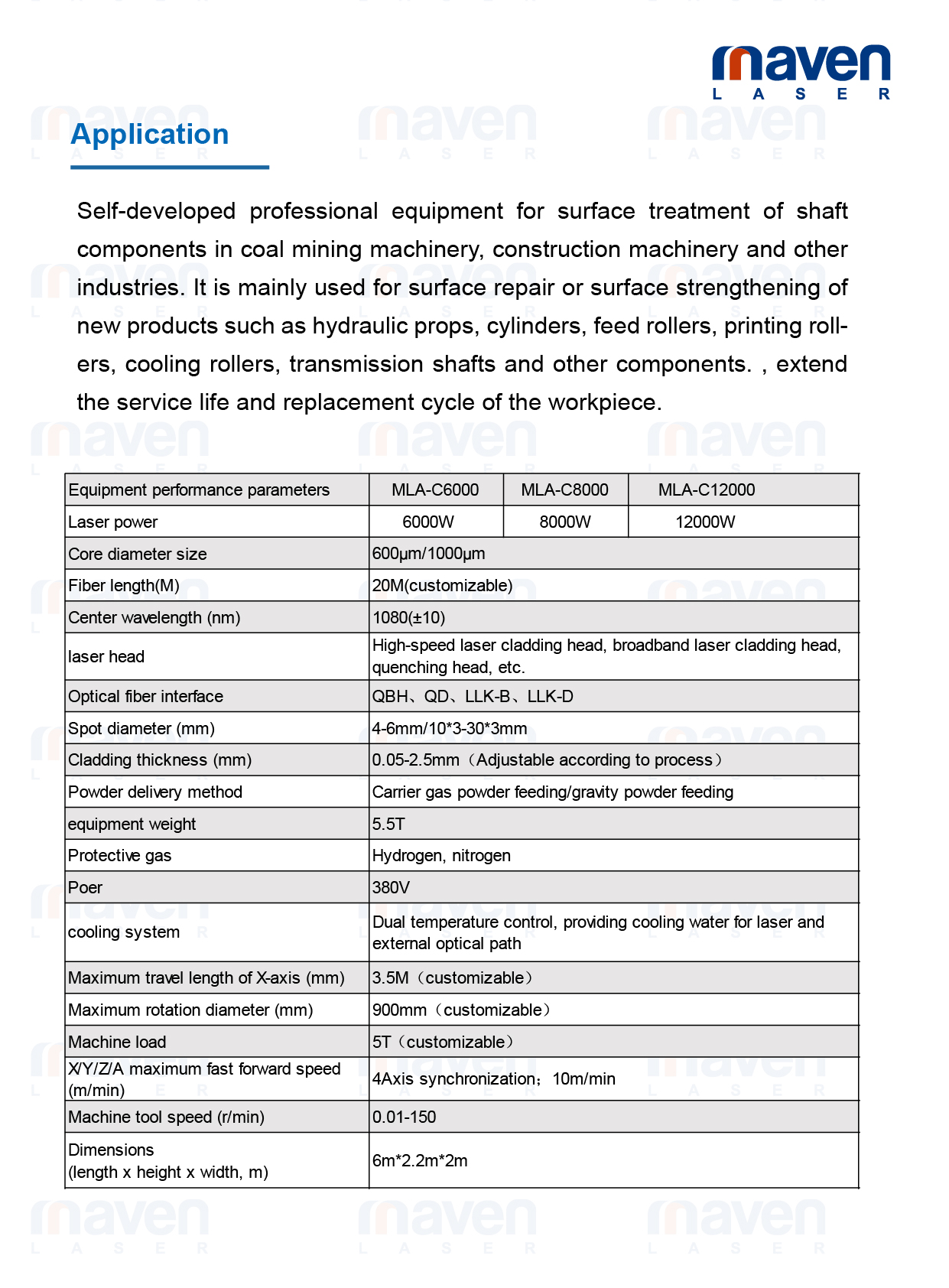

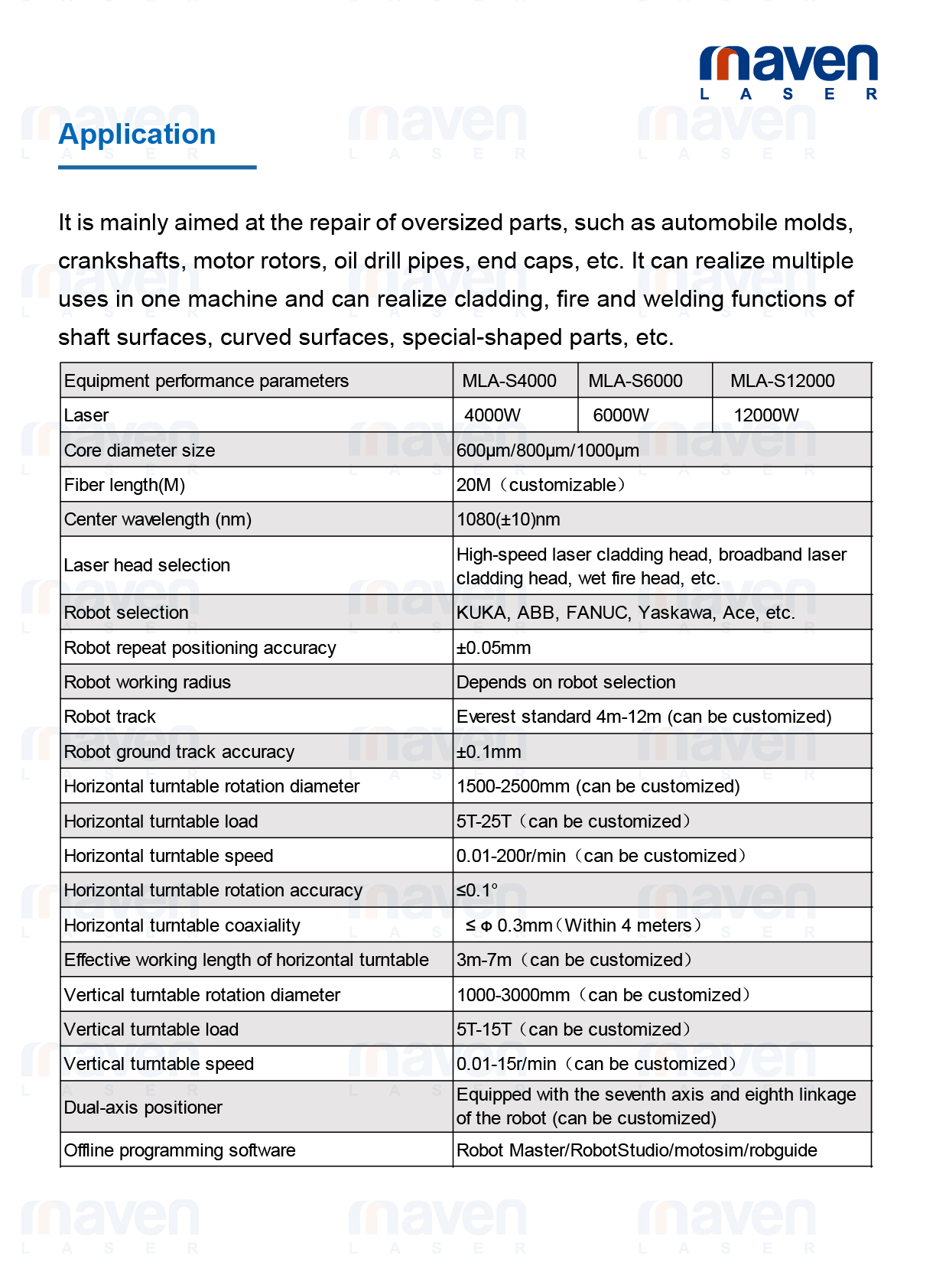

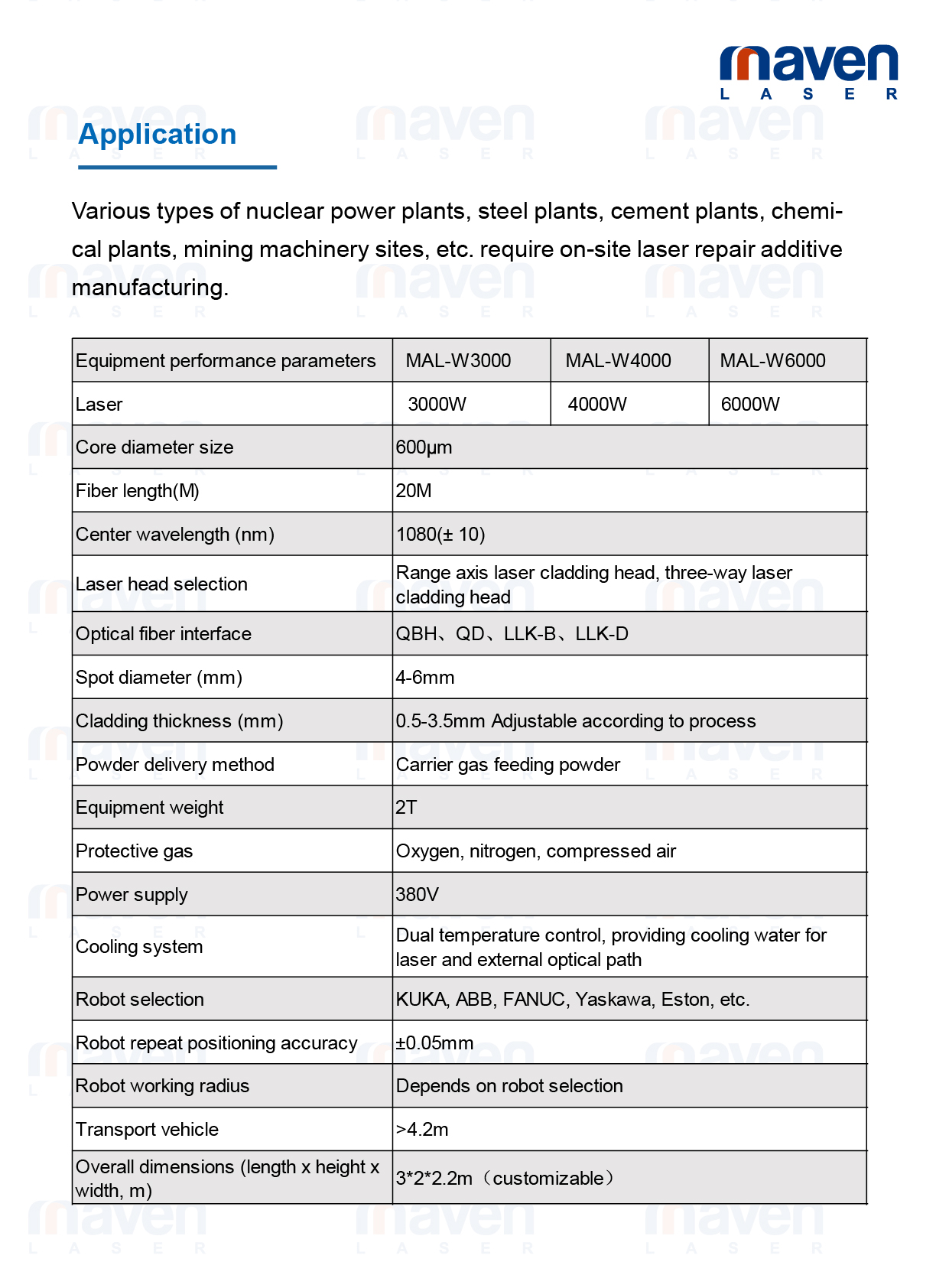

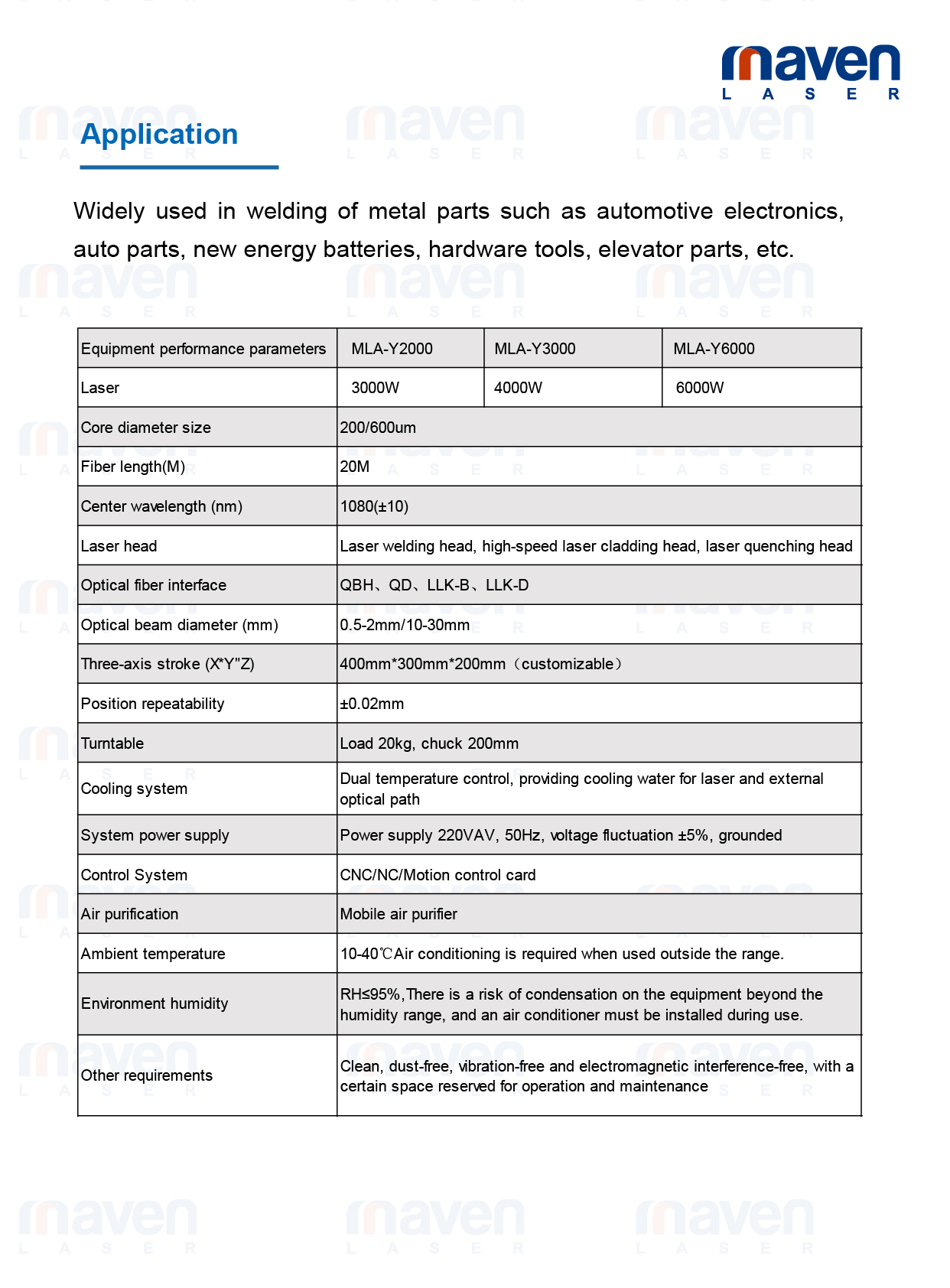

Na'ura na musamman Laser cladding quenching kayan aiki

Rufe Lasersabuwar fasaha ce ta gyaran fuska. yana ƙara claddingmaterial zuwa saman ƙasan kuma yana amfani da katako mai ƙarfi-densitylaser don haɗa shi tare da ƙaramin bakin ciki a saman ƙasan don samar da ƙaramin bakin ciki a saman ƙasan. lt ne a karfe bonding ƙarar cladding Layer tare da low dilution kudi. Laser narkewa iya cimma girma gyare-gyare ko surface ƙarfafa workpiece, da kuma inganta lalata juriya ko sa juriya na workpiece sur-face, wanda ba kawai gana da bukatun ga takamaiman yi na kayan surface, amma kuma ceton babban adadin daraja abubuwa.Rufe LaserAn yi amfani da fasaha sosai a fannoni daban-daban kamar su jiragen sama, soja, man fetur, masana'antar sinadarai, kayan aikin likitanci, da dai sauransu. Hakanan ana iya amfani da shi don sake keɓantattun sassa, da ceto albarkatun ƙasa da tsadar kayayyaki da masana'antu.