Ci gaba da Fiber Laser Welding Machine DonMatashin farantin zafi Canja wurin Farantin.

A cikin duniyar masana'antar masana'antu da ke ci gaba da haɓakawa, buƙatar ingantaccen hanyoyin samar da inganci ba ta taɓa yin girma ba.

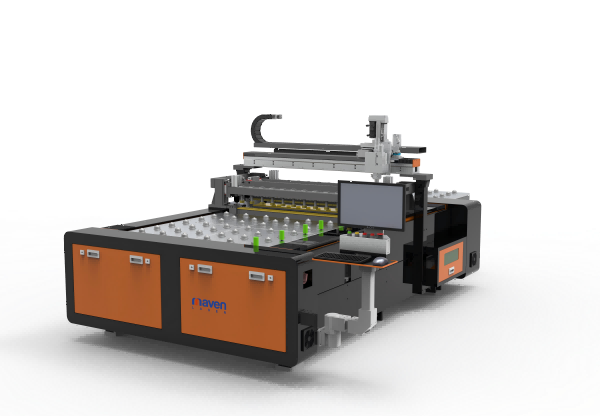

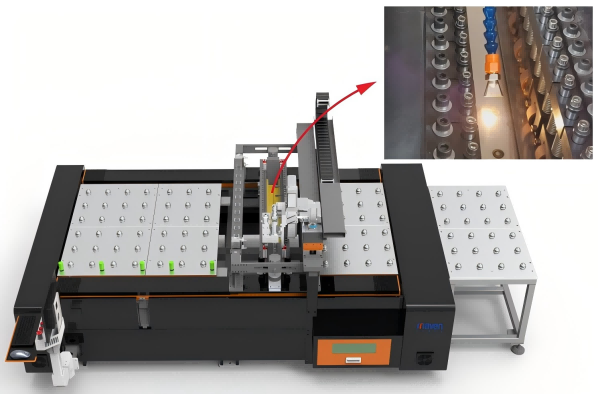

Daya daga cikin mafi m ci gaba a cikin wannan filin shi ne ci gaba da fiber Laser waldi inji, musamman a lokacin da ake amfani da samar da matashin kai farantin zafi canja wurin faranti.

Wannan haɗin fasaha da ƙira yana jujjuya yadda masana'antu ke ɗaukar hanyoyin canja wurin zafi.

Koyi game da farantin zafi canja wurin farantin

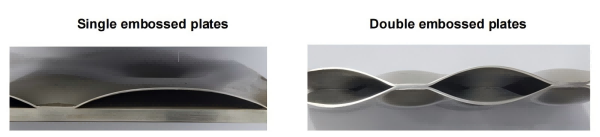

Farantin zafi canja wurin farantin matashin kai shine na yau da kullun mai musayar zafi da ake amfani dashi a cikin tsarin kamar kwandishan, kayan sanyi da hasumiya mai sanyaya.

Ka'idar aikinsa ita ce yin amfani da kwararar matakai biyu da ka'idar canja wurin zafi don canja wurin zafi.

Kwancen kwanon rufi ya ƙunshi jerinlayi daya faranti karfe.Ana amfani da gefe ɗaya na farantin don canja wurin adadin adadin abin da ake kira mai zafi;Ana amfani da ɗayan gefen farantin don canja wurin zafin kayan da ake sanyaya, wanda ake kira gefen sanyi.

The rawar da ci gaba da fiber Laser waldi

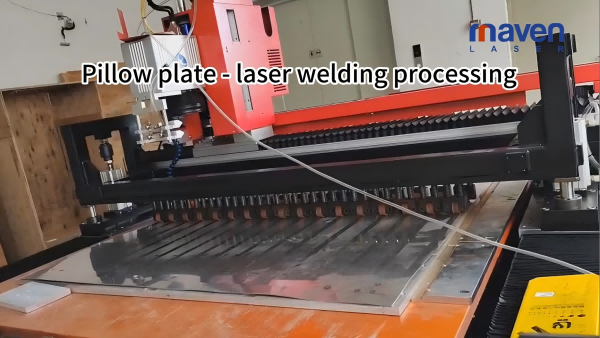

Ci gaba da fiber Laser waldi inji taka muhimmiyar rawa a masana'antu na matashin kai farantin zafi canja wurin faranti. Wannan ci-gaba fasahar walda yana amfani da ci gaba da fiber Laser katako don ƙirƙirar daidai kuma mai ƙarfi welds. Idan aka kwatanta da hanyoyin walda na gargajiya, waɗanda suke ɗaukar lokaci kuma suna iya lalata amincin kayan, walƙiyar fiber Laser yana da fa'idodi da yawa:

1) Madaidaici da Inganci: Ƙarfin Laser mai ƙarfi yana ba da damar walƙiya madaidaicin gaske, yana tabbatar da ƙaƙƙarfan ƙira na bolster ya kasance cikakke.

Wannan madaidaicin yana da mahimmanci don samun ingantacciyar hanyar canja wurin zafi.

2) Gudun da inganci: Ci gaba da walƙiya Laser fiber yana da sauri fiye da hanyoyin walda na gargajiya. Wannan gudun ba kawai yana ƙara yawan aiki ba har ma yana rage farashin aiki, yana mai da shi zaɓi mai ban sha'awa ga masana'antun.

3) Mafi ƙarancin Yankin da Ya Shafi Zafi: Halayen mayar da hankali na Laser yana rage girman yankin da zafi ya shafa, ta haka zai rage haɗarin nakasawa ko lalata kayan da ke kewaye.

Wannan kadarar tana da mahimmanci musamman a cikin samar da faranti na canja wurin zafi, inda amincin kayan abu yake da mahimmanci.

4) Versatility: Ci gaba da fiber Laser waldi inji iya walda iri-iri na kayan, ciki har da bakin karfe da aluminum, wanda aka saba amfani da matashin kai farantin zafi canja wurin faranti.

Wannan versatility yana bawa masana'antun damar daidaitawa da buƙatun aikin daban-daban ba tare da saka hannun jari a tsarin walda da yawa ba.

Aikace-aikacen masana'antu

Haɗuwa da injunan waldawa na fiber Laser mai ci gaba a cikin samar da faranti na zafi canja wurin faranti ya yi tasiri sosai a kan masana'antu daban-daban.

Misali, a cikin masana'antar abinci da abin sha, waɗannan faranti suna da mahimmanci ga tsarin pasteurization da tsarin sanyaya, wanda inganci da tsabta suke da mahimmanci. A cikin masana'antun sinadarai ana amfani da su a cikin reactors da masu musayar zafi inda ba za a iya watsi da ingantaccen aiki ba.

Bugu da ƙari, masana'antar HVAC tana fa'ida daga ingantattun kaddarorin thermal na bangarorin matashin kai, suna ba da damar ingantaccen tsarin dumama da sanyaya. Yayin da masana'antu ke ƙara mayar da hankali kan dorewa, ikon samar da ingantattun hanyoyin canja wurin zafi da rage yawan amfani da makamashi ya zama babban fa'ida mai fa'ida.

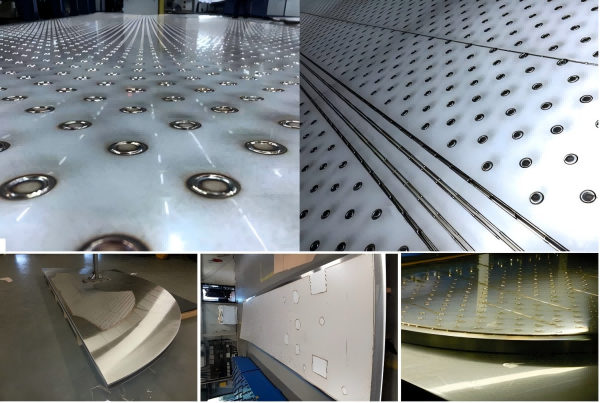

Wasu Misali

A karshe

Ci gaba da fiber Laser waldi inji wakiltar wani babban tsalle gaba a matashin kai farantin zafi canja wurin farantin masana'antu.

Ta hanyar haɗa daidaito, saurin gudu da haɓakawa, fasahar ba kawai inganta ingancin samfurin ƙarshe ba amma har ma yana taimakawa haɓaka ingantaccen tsarin masana'antu gaba ɗaya. Kamar yadda masana'antu ke ci gaba da neman sabbin hanyoyin magance buƙatun canjin zafi, haɗin gwiwa tsakanin waldawar fiber Laser da fasaha mai ƙarfi zai taka muhimmiyar rawa wajen tsara makomar masana'antu.

Lokacin aikawa: Oktoba-17-2024