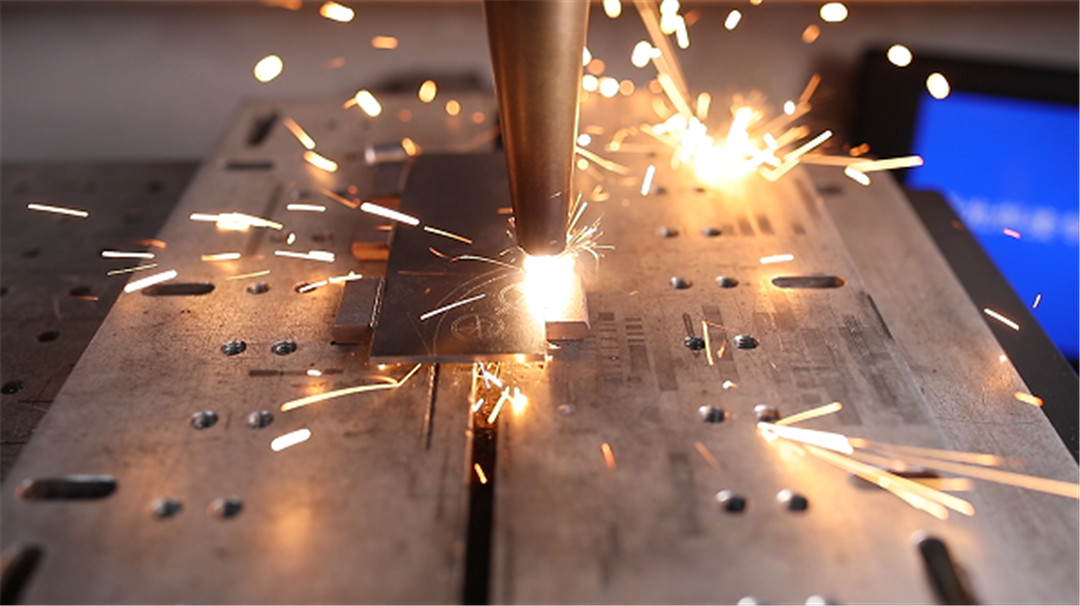

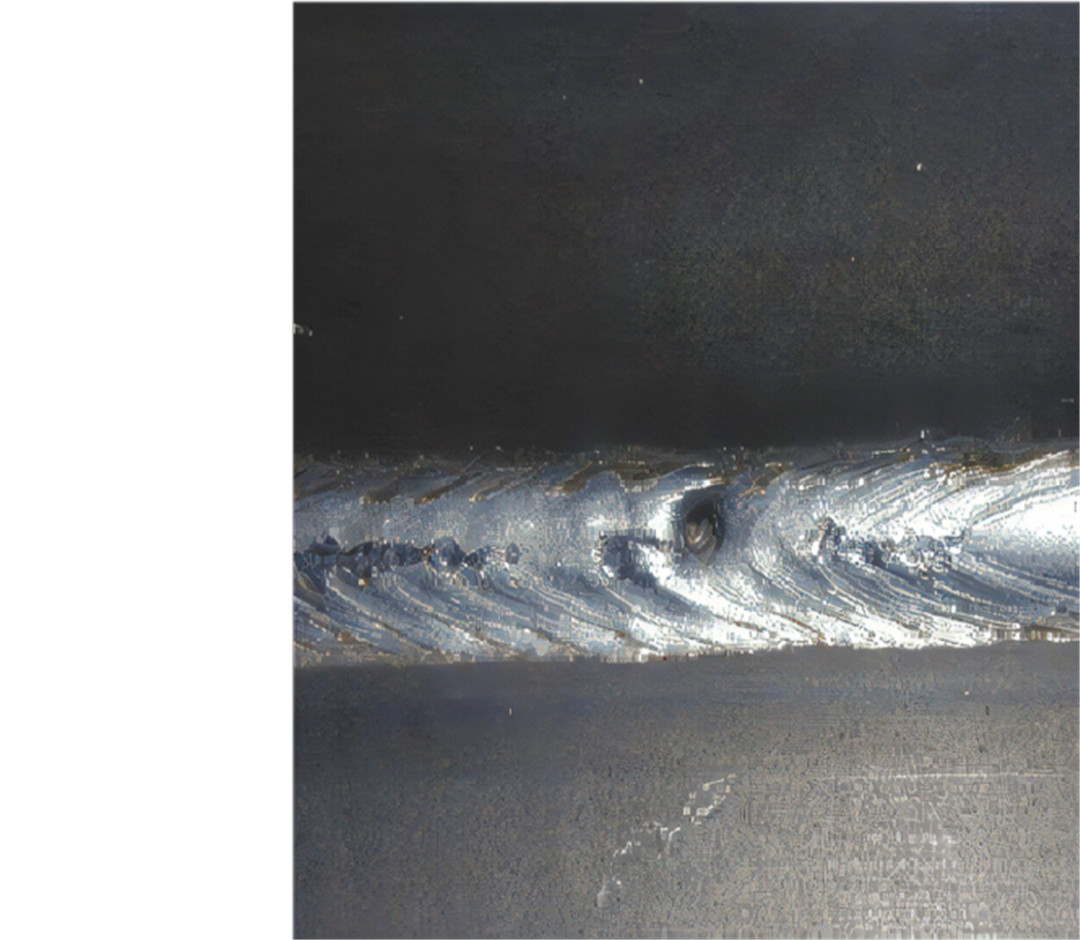

1. Matsala: Slag splash

A cikin aikin waldawar Laser, kayan narkewar ya fantsama a ko'ina kuma yana manne da saman kayan, yana sanya barbashi na ƙarfe suna bayyana a saman kuma suna shafar kyawun samfurin.

Dalilin matsalar: spatter na iya zama saboda ƙarfin da ya wuce kima wanda ke haifar da narkewa da sauri, amma kuma saboda yanayin kayan ba shi da tsabta, ko gas yana da ƙarfi sosai.

Magani: 1, daidaitawar wutar lantarki mai dacewa; 2, kula da kayan aikin tsaftacewa; 3, rage yawan iskar gas.

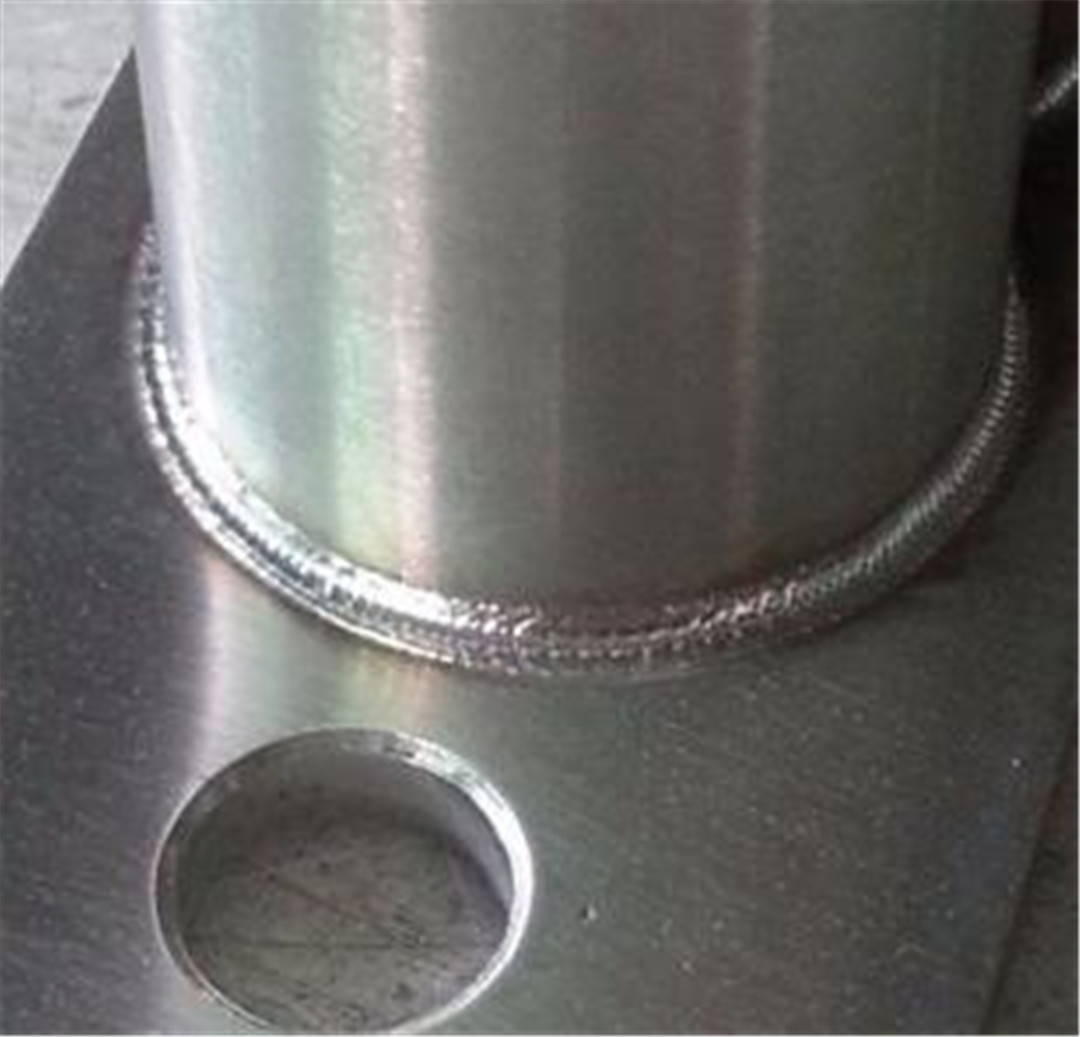

2. Matsala: Kabuwar walda ya yi yawa

Welding zai gano cewa Weld Seam yana da matukar muhimmanci fiye da matakin al'ada, wanda ya haifar da sikirin mai, wanda yayi kama da rashin kulawa.

Dalilin matsalar: saurin ciyarwar waya yana da sauri sosai, ko kuma saurin walda yana jinkiri.

Magani: 1. Rage saurin ciyarwar waya a cikin tsarin sarrafawa; 2. Ƙara saurin walda.

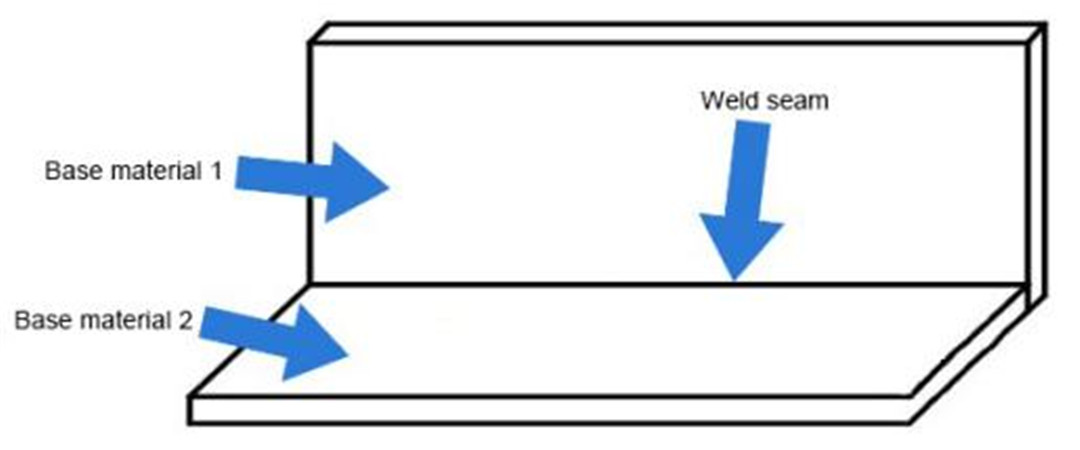

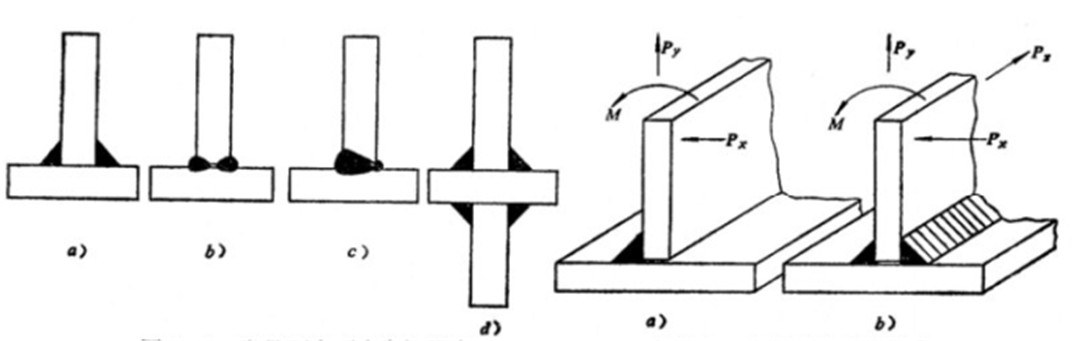

3. Matsala: Welding diyya

Welding ba tare da solidification a tsarin gidajen abinci da kuma m matsayi na iya haifar da cikakken gazawar waldi.

Dalilin matsalar: matsayi mara kyau a lokacin walda; matsayi mara daidaituwa na ciyarwar waya da hasken wuta na laser.

Magani: 1. Daidaita ɓangarorin laser da kusurwar lilo a cikin jirgi; 2. Bincika haɗin kai tsakanin mai ba da waya da shugaban laser don sabawa.

4. Matsala: Launin walda yayi duhu sosai

Lokacin walda bakin karfe, aluminum gami da sauran kayan, launin weld ya yi duhu sosai zai sa walda da farfajiyar kayan ke haifar da bambanci mai ƙarfi, yana tasiri sosai ga kyakkyawa.

Dalilin matsalar: ikon Laser yana da ƙanƙanta wanda ke haifar da ƙarancin konewa, ko saurin walda yana da sauri.

Magani: 1. daidaita wutar lantarki; 2. daidaita saurin walda.

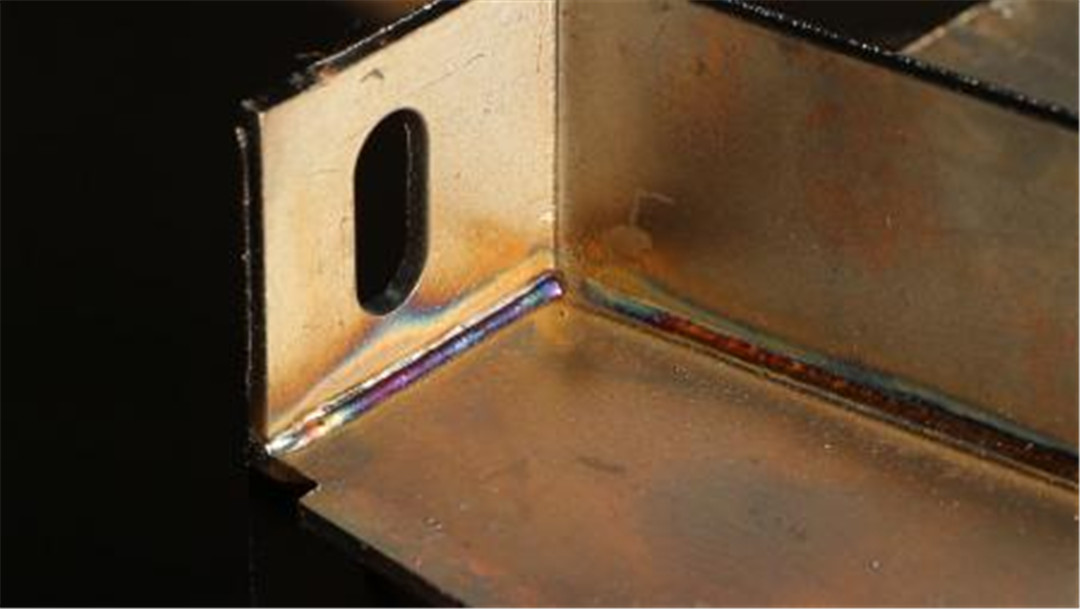

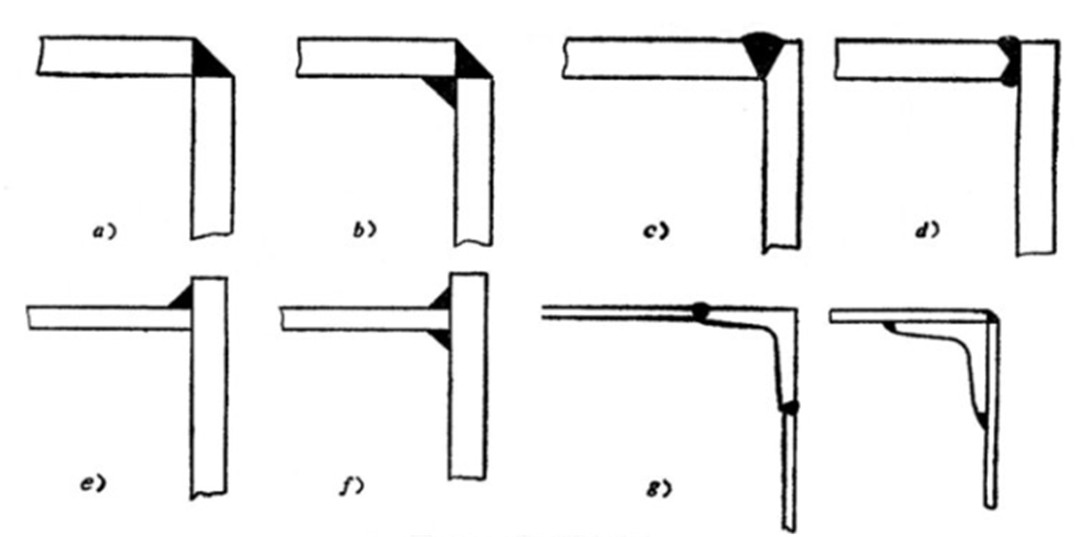

5. Matsala: Ƙirar walda mara daidaituwa

Lokacin walda sasanninta na ciki da na waje, sasanninta ba a daidaita su zuwa sauri ko matsayi, wanda zai iya haifar da rashin daidaituwa a sasanninta cikin sauƙi, yana shafar ƙarfin walda da kyawun walda.

Dalilin matsalar: yanayin walda mara kyau.

Magani: Daidaita mayar da hankali a cikin tsarin sarrafa Laser ta yadda shugaban Laser na hannu zai iya aiwatar da ayyukan walda a gefe.

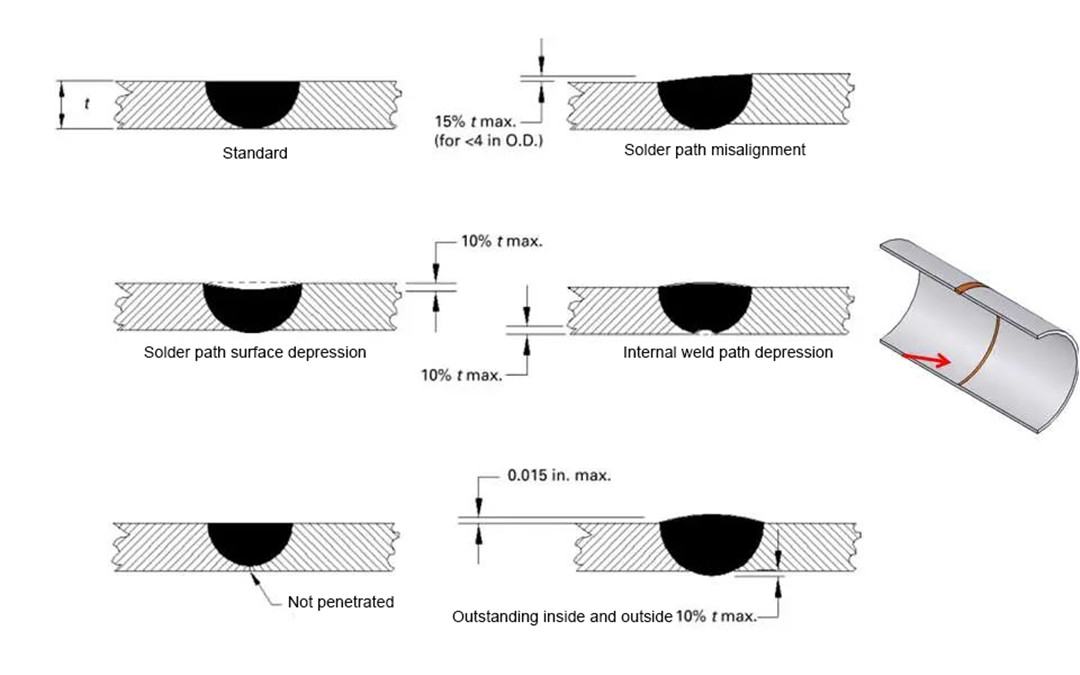

6. Matsala: baƙin ciki na walda

Dents a cikin welded haɗin gwiwa zai haifar da rashin isasshen ƙarfin walda da samfuran da ba su cancanta ba.

Dalilin matsalar: Ƙarfin laser yana da girma sosai, ko kuma an saita mayar da hankali ga laser ba daidai ba, yana haifar da narke tafkin ya yi zurfi sosai kuma kayan ya zama mai narke, wanda hakan yana haifar da baƙin ciki na weld.

Magani: 1. Daidaita wutar lantarki; 2. Daidaita mayar da hankali na laser.

7. Matsala: kauri weld ba uniform

Weld dinki wani lokacin yayi girma sosai, wani lokacin yayi karanci, ko kuma na al'ada.

Dalilin matsalar: hasken wuta ko ciyarwar waya ba matsala bane.

Magani: Duba kwanciyar hankali na Laser da mai ciyar da waya, gami da ƙarfin wutar lantarki, tsarin sanyaya, tsarin sarrafawa, waya ƙasa, da sauransu.

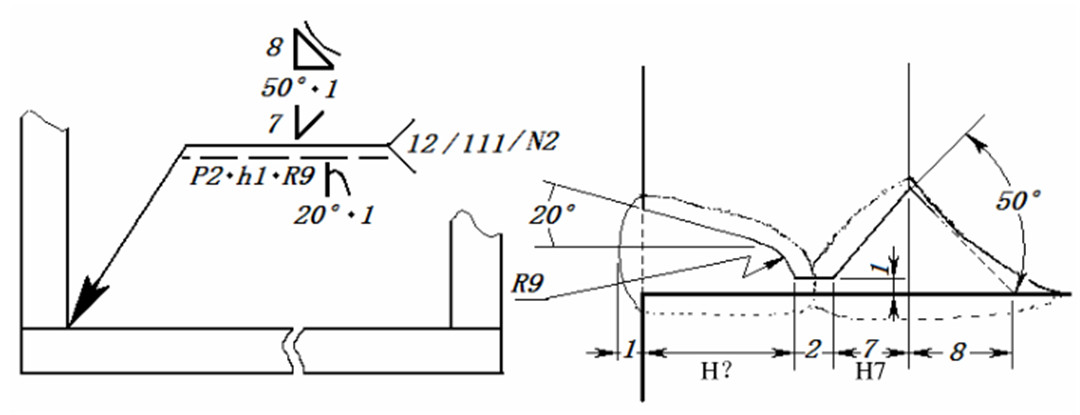

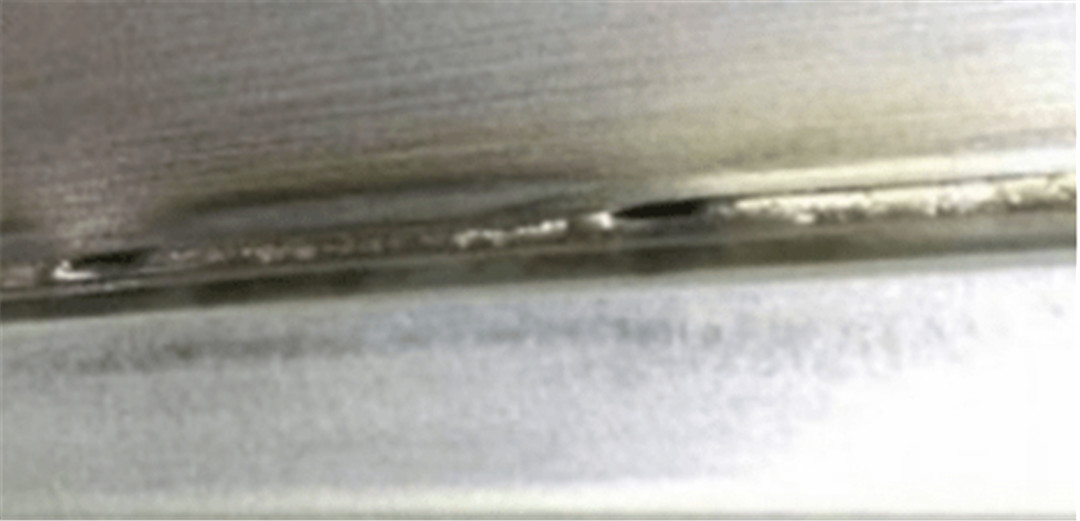

8. Matsala: Cizon baki

Cizo gefen yana nufin walda kuma kayan ba a haɗa su da kyau ba, beveling da sauran yanayi, don haka yana shafar ingancin walda.

Dalilin matsalar: saurin waldawa yana da sauri, wanda ya haifar da narke tafkin ba a rarraba a ko'ina a ɓangarorin biyu na kayan, ko rata na kayan yana da girma, kayan filler bai isa ba.

Magani: 1. Daidaita ƙarfin laser da sauri bisa ga ƙarfin kayan aiki da girman girman walda; 2. Yi aikin cikawa ko gyara daga baya.

Maven Laser Automation Co., Ltd. (Maven Laser a takaice) shi ne babban manufacturer na Laser tsarin da kuma sana'a aiki da kai mafita, located in Shenzhen, China, kafa a 2008. Our sana'a kayayyakin ne: Laser tsaftacewa inji, Laser waldi inji, robot waldi inji da dandamali waldi na'ura, idan kuna da tambayoyi masu sana'a, barka da zuwa tuntuɓar mu.

Lokacin aikawa: Nuwamba 18-2022