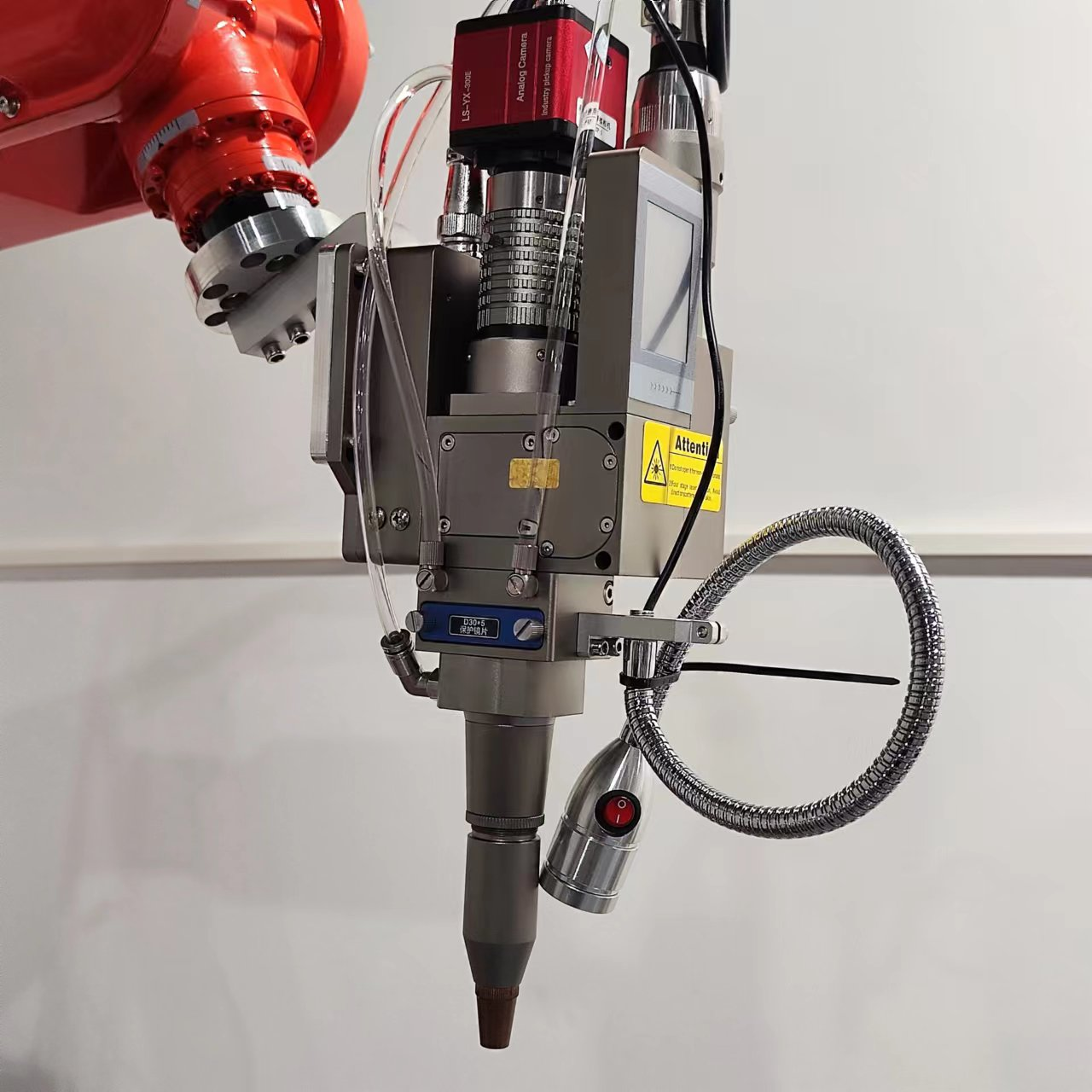

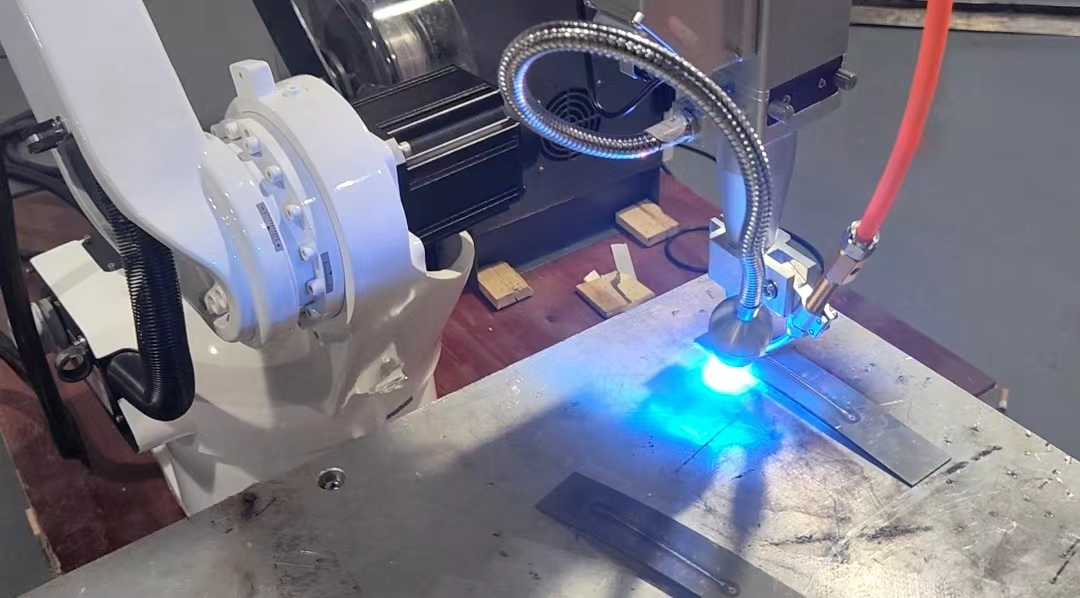

Fasahar haɗawa ta Laser, ko fasahar waldawa ta Laser, tana amfani da katako mai ƙarfi na Laser don mayar da hankali da daidaita hasken farfajiyar abu, kuma saman kayan yana ɗaukar makamashin Laser kuma ya canza shi zuwa makamashin zafi, yana haifar da kayan don yin zafi a cikin gida da narke. , biyo bayan sanyaya da ƙarfafawa don cimma haɗin haɗin kai ko kayan da ba su da kama. Tsarin waldawar Laser yana buƙatar ƙarfin ƙarfin Laser na 104zuwa 108W/cm2. Idan aka kwatanta da hanyoyin walda na gargajiya, walƙiya ta Laser tana da fa'idodi masu zuwa.

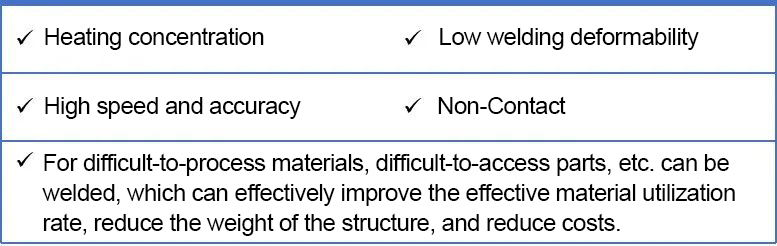

Fasahar haɗawa ta Laser, ko fasahar waldawa ta Laser, tana amfani da katako mai ƙarfi na Laser don mayar da hankali da daidaita hasken farfajiyar abu, kuma saman kayan yana ɗaukar makamashin Laser kuma ya canza shi zuwa makamashin zafi, yana haifar da kayan don yin zafi a cikin gida da narke. , biyo bayan sanyaya da ƙarfafawa don cimma haɗin haɗin kai ko kayan da ba su da kama. Tsarin waldawar Laser yana buƙatar ƙarfin ƙarfin Laser na 104zuwa 108W/cm2. Idan aka kwatanta da hanyoyin walda na gargajiya, walƙiya ta Laser tana da fa'idodi masu zuwa.

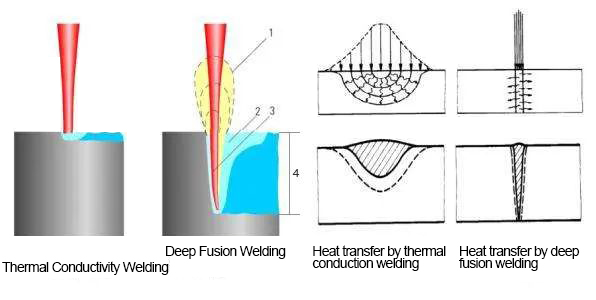

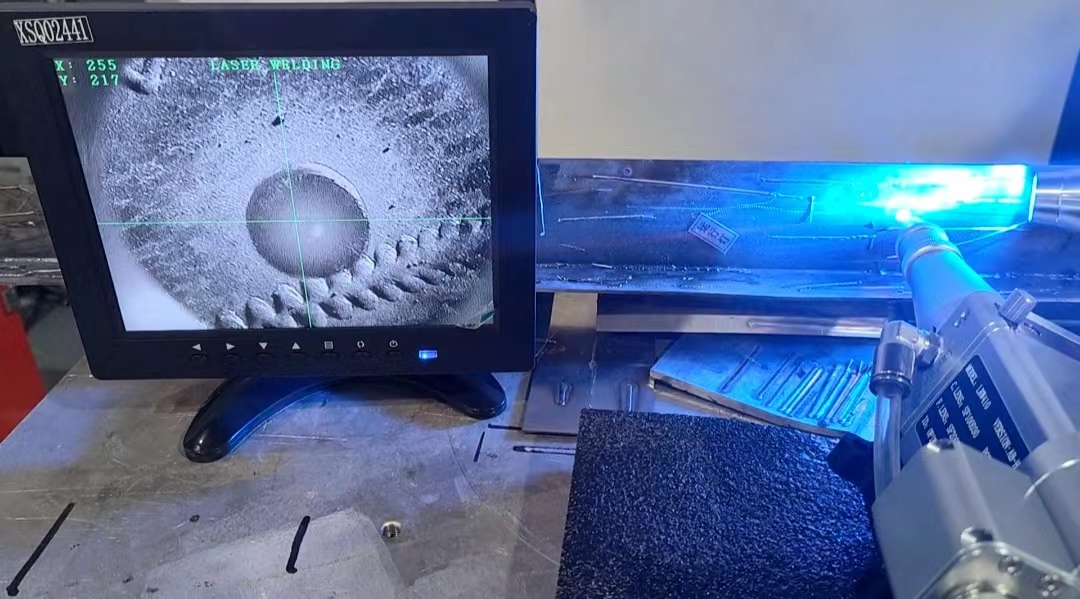

1-plasma girgije, 2-narke abu, 3-keyhole, 4-zurfin Fusion

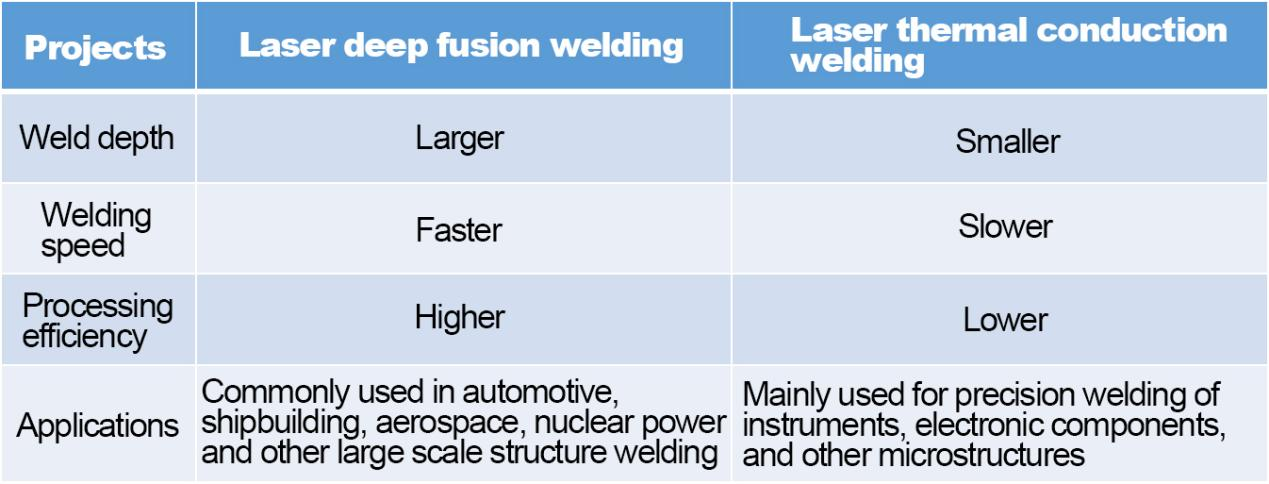

Saboda kasancewar maɓalli na maɓalli, katako na laser, bayan da ya haskaka cikin cikin maɓalli, zai ƙara yawan shayar da Laser ta hanyar kayan aiki kuma yana inganta samar da narkakken tafkin bayan watsawa da sauran tasiri, ana kwatanta hanyoyin walda biyu. mai bi.

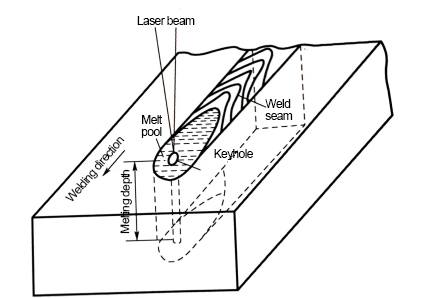

Hoton da ke sama yana ba da tsarin waldawar laser na kayan abu iri ɗaya da kuma tushen haske iri ɗaya, tsarin juyawa makamashi ana yin shi ne kawai ta hanyar maɓalli, maɓalli da narkakken ƙarfe kusa da bangon ramin yana motsawa tare da gaba na katako na Laser, Karfe da aka narkar da shi yana motsa ramin maɓalli daga iskar da aka bari a baya don cikawa da kuma bayan daɗaɗɗen ruwa, yana samar da ɗinkin walda.

Idan kayan da za a yi waldawa wani ƙarfe ne mai ban sha'awa, kasancewar bambance-bambance a cikin kaddarorin thermal zai yi tasiri mai yawa akan tsarin walda, kamar bambance-bambance a wuraren narkewa, haɓakar zafin jiki, takamaiman ƙarfin zafi, da haɓaka ƙima na kayan daban-daban, sakamakon haka. a walda danniya, walda nakasawa, da kuma canje-canje a cikin crystallization yanayi na welded hadin gwiwa karfe, haifar da raguwa a inji Properties na weld.

Sabili da haka, bisa ga halaye daban-daban na wurin walda, tsarin walda ya haɓaka walƙiyar Laser filler, Laser brazing, walƙiyar laser dual-beam, walƙiyar haɗaɗɗun Laser, da sauransu.

Laser Waya Cika Welding

A cikin Laser walda tsari na aluminum, titanium da jan karfe gami, saboda da low sha na Laser haske (<10%) a cikin wadannan kayan, da photo generated plasma yana da wani garkuwar Laser haske, don haka yana da sauki samar da spatter da kuma. haifar da haɓakar lahani kamar porosity da fasa. Bugu da kari, da waldi ingancin kuma ya shafi lokacin da rata tsakanin workpieces ne ya fi girma fiye da tabo diamita a lokacin bakin ciki farantin sputtering.

A cikin magance matsalolin da ke sama, ana iya samun kyakkyawan sakamako na walda ta amfani da hanyar kayan filler. Filler na iya zama waya ko foda, ko kuma ana iya amfani da hanyar da aka riga aka saita. Saboda ƙaramin wurin da aka mayar da hankali, walda ya zama kunkuntar kuma yana da ɗan madaidaicin siffa a saman bayan an yi amfani da kayan filler.

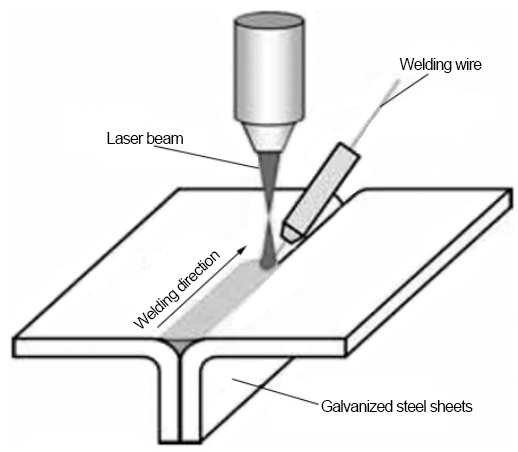

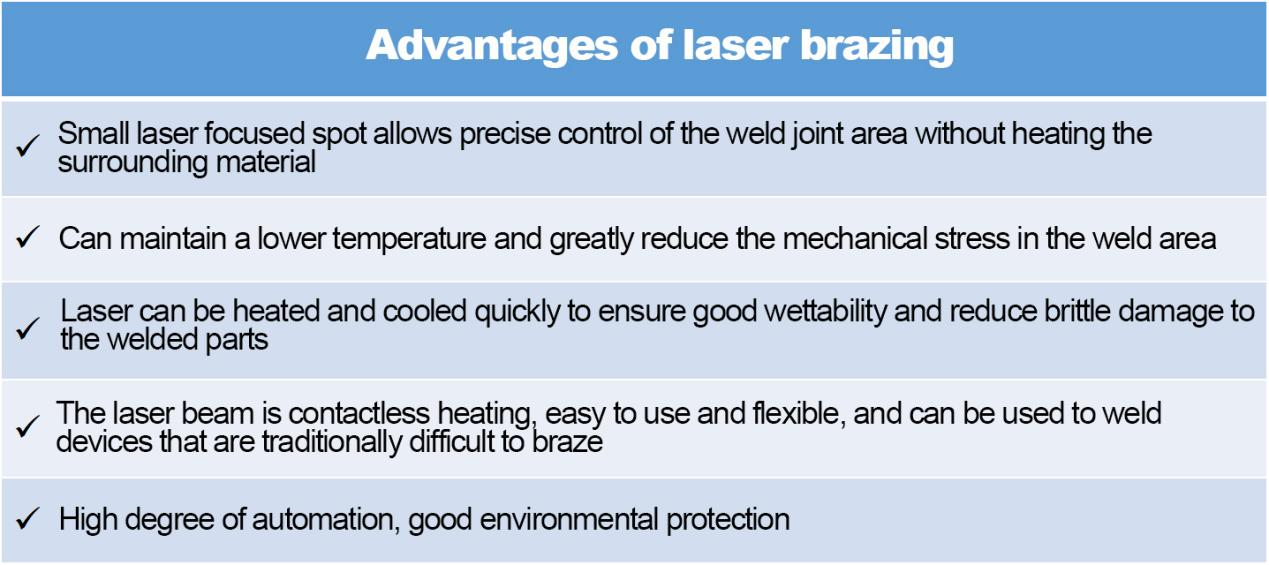

Laser Brazing

Ba kamar walda ba, wanda ke narkar da sassa biyu masu walda a lokaci guda, brazing yana ƙara kayan filler tare da ƙaramin narkewa fiye da kayan tushe zuwa farfajiyar weld, yana narke kayan filler don cike gibin a yanayin zafi ƙasa da narkewar kayan tushe. aya kuma mafi girma fiye da wurin narkewar kayan filler, sannan kuma ya taru don samar da ingantaccen weld.

Brazing ya dace da na'urorin microelectronic masu zafin zafi, faranti na bakin ciki, da kayan ƙarfe masu canzawa.

Bugu da ari, ana iya ƙara shi azaman brazing mai laushi (<450 ° C) da brazing mai wuya (> 450 ° C) dangane da zafin jiki wanda kayan aikin brazing ke dumama.

Dual Beam Laser Welding

Dual-beam waldi yana ba da damar sassauƙa da dacewa da sarrafa lokaci da matsayi na hasken laser, don haka daidaita rarraba makamashi.

Ana amfani dashi galibi don waldawar al'ada na aluminum da magnesium gami, splice da walƙiya faranti don motoci, brazing Laser da walƙiya mai zurfi.

Ana iya samun katako biyu ta hanyar laser masu zaman kansu guda biyu ko ta hanyar tsagewar katako tare da mai raba katako.

Biyu katako na iya zama hade da Laser tare da daban-daban lokaci yanki halaye (pulsed vs. ci gaba), daban-daban wavelengths (tsakiyar infrared vs. bayyane raƙuman ruwa) da kuma daban-daban iko, wanda za a iya zaba bisa ga ainihin sarrafa kayan.

4.Laser Composite Welding

Saboda yin amfani da Laser katako a matsayin kawai zafi tushen, guda zafi tushen Laser waldi yana da wani low makamashi canji kudi da kuma amfani kudi, da weld tushe abu tashar jiragen ruwa dubawa ne mai sauki don samar da misalignment, sauki don samar da pores da fasa da sauran shortcomings. Domin warware wannan matsala, za ka iya amfani da dumama halaye na sauran zafi kafofin inganta dumama na Laser a kan workpiece, yawanci ake kira Laser composite waldi.

Babban nau'i na walƙiya mai haɗaɗɗun Laser shine haɗakarwa ta Laser da baka na lantarki, tasirin 1 + 1> 2 kamar haka.

bayan Laser katako kusa da amfani da baka,da electron yawa an rage muhimmanci, girgijen plasma da aka samar ta hanyar waldawar laser yana diluted, wandana iya sa yawan shan Laser ya inganta sosai, yayin da arc a kan tushe kayan preheating zai kara ƙara yawan sha na Laser.

2. babban amfani da makamashi na arc da dukaza a ƙara amfani da makamashi.

3, da Laser waldi yankin na mataki ne kananan, sauki don haifar da misalignment na walda tashar jiragen ruwa, yayin da thermal mataki na baka ne babba, wanda zai iya.rage rashin daidaituwa na tashar walda. A lokaci guda, daAna inganta ingancin walda da ingancin bakasaboda mayar da hankali da kuma jagoranci sakamako na Laser katako a kan baka.

4, Laser waldi tare da high ganiya zazzabi, babban zafi-tasiri yankin, da sauri sanyaya da solidification gudun, sauki don samar da fasa da pores; yayin da yankin da zafi ya shafa yana da ƙananan, wanda zai iya rage yawan zafin jiki, sanyaya, saurin ƙarfafawa,zai iya ragewa da kawar da samar da pores da fasa.

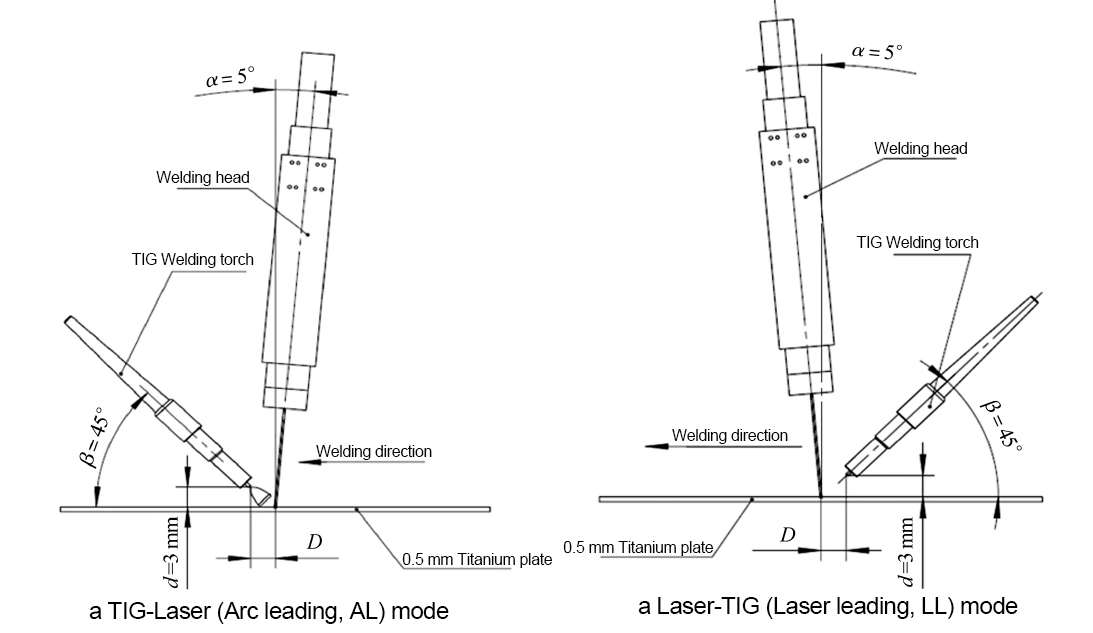

Akwai nau'i biyu na gama-gari na walƙiya mai haɗawa da Laser: Laser-TIG composite waldi (kamar yadda aka nuna a ƙasa) da Laser-MIG composite waldi.

Akwai kuma wasu nau'o'in walda kamar Laser da Plasma arc, Laser da inductive heat source fili waldi.

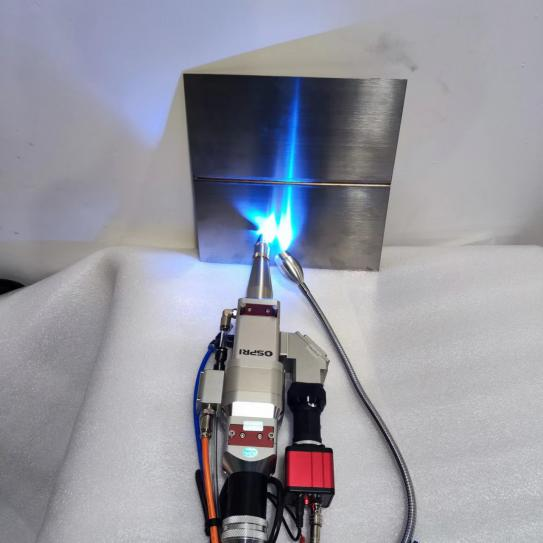

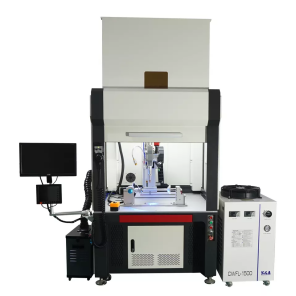

Game da MavenLaser

Maven Laser shine jagoran aikace-aikacen masana'antu na Laser a China kuma mai ba da izini na hanyoyin sarrafa Laser na duniya. Mun warai gane ci gaban Trend na masana'antu masana'antu, kullum wadãtar da mu kayayyakin da mafita, dace a kan binciko da hadewa da aiki da kai, informationization da hankali tare da masana'antu masana'antu, samar da Laser waldi kayan aiki, Laser alama kayan aiki, Laser tsaftacewa kayan aiki da Laser zinariya da azurfa kayan ado. yankan kayan aiki don masana'antu daban-daban ciki har da cikakken jerin wutar lantarki, da ci gaba da fadada tasirin mu a fagen kayan aikin Laser.

Lokacin aikawa: Janairu-13-2023