1.Advantages da rashin amfani na Laser walda inji da aikace-aikace ikon yinsa

Laser walda na'ura wani sabon nau'i ne na walda hanyar, tare da low bond ƙarfi, zafi shafi yankin fadi da kuma sauran fa'idodi da yawa, a halin yanzu kasuwar sarrafa karfe, Laser waldi an yi amfani sosai ko'ina, an dade ana amfani da shi a kowane fanni na rayuwa. , kamar: Kofin rufe karfe, masana'antar wayar salula, masana'antar likitanci, masana'antar kera motoci da sauran bangarorin masana'antu da yawa.

01 Amfanin na'urar waldawa ta Laser

Idan aka kwatanta da fasahar walda na gargajiya, fasahar walƙiya ta Laser ba haɗin haɗin gwiwa ba ne, tsarin aiki baya buƙatar matsa lamba, yana da saurin walƙiya mai sauri, ƙarfi mai ƙarfi, zurfin, ƙaramin naƙasa, kunkuntar weld ɗin, ƙaramin yankin da zafi ya shafa, da kuma aikin aiki. nakasawa yana da ƙananan, aikin sarrafawa mai biyo baya ya ragu, rage kayan aiki na hannu, babban sassauci, ƙarin aminci da sauran fa'idodi.

Za a iya amfani da fasahar waldawar Laser don walda kayan da ba su da ƙarfi kamar manyan ƙarfe masu narkewa, har ma da kayan da ba na ƙarfe ba kamar su yumbu da gilashin halitta, tare da kyakkyawan sakamako na walda akan kayan da aka siffa da babban sassauci. Don walda sassan da ba za a iya isa ba, ana yin waldi mai sassauƙa wanda ba na lamba ba. Za a iya raba katako na Laser a cikin lokaci da makamashi, yana ba da damar sarrafa katako da yawa a lokaci guda, yana ba da yanayi don ƙarin walƙiya daidai.

02 Abubuwan lura game da amfani da na'urorin walda na Laser

Ya kamata a lura da waɗannan abubuwa masu zuwa lokacin amfani da kayan aikin walda na Laser

(a) Matsayin ɓangaren welded yana buƙatar zama daidai sosai, tabbatar da cewa yana cikin abin da aka fi mayar da hankali na katako na Laser.

(b) Lokacin da ɓangaren welded yana buƙatar yin amfani da kayan aiki, dole ne a tabbatar da cewa matsayi na ƙarshe na ɓangaren da aka haɗa yana buƙatar daidaitawa tare da ma'aunin walda inda igiyar laser zai yi tasiri.

(c) Matsakaicin kauri mai walƙiya yana iyakance, shigar da kayan aiki tare da kauri sama da 19mm a cikin layin samarwa yana buƙatar tuntuɓar masana'anta don samar da ƙarin tallafin fasaha na ƙwararru.

03 Aikace-aikace na Laser walda inji

1. Masana'antar baturi

Wayar salula da galibin samfuran lambar batir ana amfani da walda ta Laser.

2. Bathroom kitchenware masana'antu

Laser waldi daidaici yana da mafi kyau bayyanar, don haka a cikin high-sa gidan wanka bakin karfe kayayyakin Laser alama Laser waldi yana da fadi da kewayon aikace-aikace. Irin su: hannaye, famfo, wukake na bakin ciki da mafi yawan hanyar tare da alamar laser na samar da LOGO na kamfani, manyan kettles na lantarki da sauran hatimi suma suna amfani da walƙiya na laser don kammalawa. Kitchenware, tableware kungiyar walda butt waldi, bude mold yi da gyara da canza mold a kan aiwatar da amfani.

3. Kayayyakin dijital, wayoyin hannu, masana'antar kwamfuta

sarrafa Laser saboda daidaitattun fasahar sarrafa kayan aiki, a cikin dijital, wayar salula, aikace-aikacen filin kwamfuta sun fi shahara kamar: wayoyin hannu, MP4, waldawar Laser harsashi MP3, layin dubawa, kwamfutocin tafi-da-gidanka, na'urorin fiber optic spot waldi, mai haɗa chassis na kwamfuta. .

4. Masana'antar Injiniya

Walda kayan aikin tsarkakewa, walƙiya sassa na lantarki, gyaran haɗin haɗi.

5. Electronics, lantarki masana'antu

Tunda sarrafa Laser hanya ce da ba ta tuntuɓar sadarwa ba, baya haifar da extrusion na inji ko damuwa na inji, don haka musamman ya dace da buƙatun sarrafawa na masana'antar lantarki. Kamar su: masu canzawa, inductor, haši, tashoshi, fiber optic connectors, na'urori masu auna firikwensin, masu canza wuta, masu sauyawa, batirin wayar salula, abubuwan microelectronic, hadedde hanyoyin da'ira da sauran walda.

6. Masana'antar kayan ado

Tun da sarrafa Laser yana da kyau sosai, yana da kyau ga masu daraja da ƙananan samfurori a cikin masana'antar kayan ado. Yayin da katako mai mayar da hankali na Laser yana da kyau sosai, ana ɗaukaka shi ta microscope don haɓaka ƙananan sassa na kayan ado da kuma gane ainihin walƙiya. Laser tabo welder kayan aiki ne da ake buƙata don haɗin sarƙoƙin kayan ado da shigar da duwatsu masu daraja.

7. Hardware, kayan aiki, masana'antar kayan aiki

Kayan aiki, firikwensin, kayan dafa abinci, ƙungiyar kayan aikin walda walda, buɗaɗɗen ƙirar ƙira da gyara da canza ƙirar yayin amfani. Walda mara kyau na bakin karfe tableware, walda a haɗin mita core.

8. Motoci, masana'antar abin hawa na lantarki

Laser sarrafa don ba lamba aiki, babu gurbatawa ga samfurin, high gudun, mafi dace da bukatun high-karshen mota mabukaci kayayyakin samar tsari, kamar mota bugun kira waldi, bawul waldi, fistan zobe waldi, mota Silinda gasket waldi, bututu mai shaye-shaye, waldawar tacewa, walda na janareta na aminci na mota. Yanke sassa na Laser a cikin gwaji da ƙananan matakan samar da motoci, da waldar batura don motocin lantarki.

9. Masana'antar kayan aikin hasken wutar lantarki

Laser aiki ne yadu amfani a Laser hasken rana cell masana'antu: kamar hasken rana silicon wafer Laser scribing yankan, hasken rana hita zafi conduction farantin waldi. Sarrafa Laser, a matsayin hanyar da ta dace da muhalli da ingantacciyar hanyar sarrafawa, za a fi amfani da ita a nan gaba.

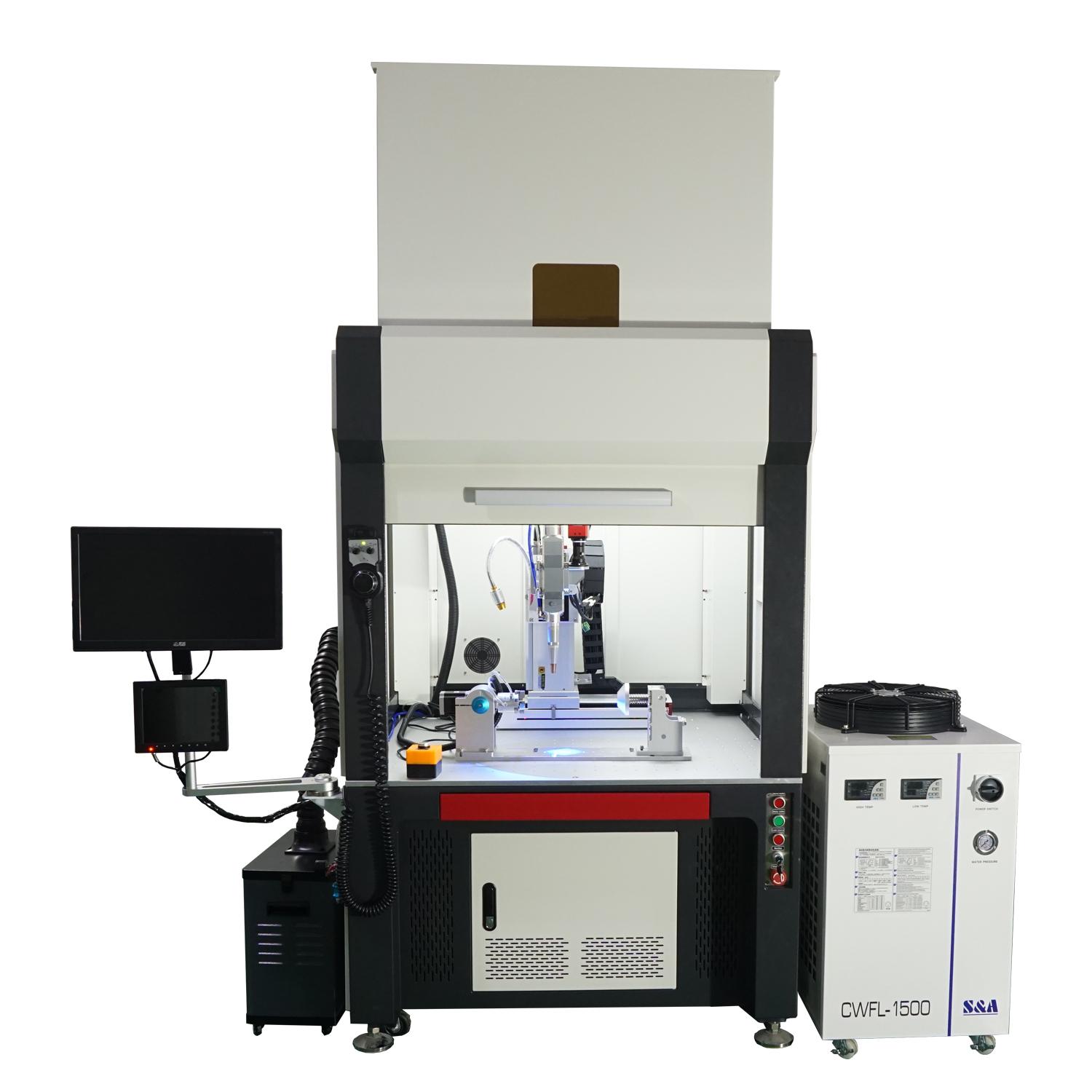

2.What Platform atomatik Laser waldi inji?

Platform atomatik Laser walda inji ne atomatik waldi na'ura da yin amfani da high-makamashi Laser bugun jini zuwa gida zafi kayan a cikin wani karamin yanki. Ana watsar da makamashin hasken wutar lantarki ta hanyar zafin zafi zuwa cikin kayan kuma kayan yana narke don samar da wani tafki na narkakkar. An yafi amfani da waldi na bakin ciki-banga kayan da daidaici sassa, da kuma iya gane lantarki waldi, butt waldi, cinya waldi, hatimi waldi, da dai sauransu Yana yana da fasali na kananan weld nisa, azumi waldi gudun, high waldi quality, babu. porosity, ingantaccen iko, babban matsayi daidaito, da sauƙin sarrafa kansa.

3.What is a handheld Laser waldi inji?

Kamar yadda sunan ke nunawa, injin walƙiya na laser na hannu nau'in kayan walda ne wanda ke buƙatar aiki da hannu. Wannan walda kayan aiki iya yi Laser waldi a kan dogon da kuma manyan workpieces. A lokacin walda, zafi shafi yankin ne kananan da kuma ba ya haifar da nakasawa, blackening da alamomi a baya na workpiece. Zurfin walda yana da girma, walda ɗin yana da ƙarfi, narkewa ya wadatar, kuma babu damuwa a cikin tafkin narkewa inda tsinkayar narkakkar kayan ya hadu da ma'aunin.

4.What ne bambanci tsakanin atomatik Laser waldi inji da hannu Laser waldi inji?

Na'urorin walda laser ta atomatik suna walƙiya ta atomatik bisa ga tsarin da aka saita bayan an saita su a cikin software; Injin walƙiya na laser na hannu, wanda kuma aka sani da walƙiya tabo, masu amfani suna amfani da su lokacin amfani da kayan walda na Laser ta hanyar ƙara girman allo.

Ana yin walda ta gani na gani da hannu kuma gabaɗaya ana kera shi ta hanyar masana'antun kayan aikin Laser don biyan bukatun mai amfani. Ƙananan masana'antun suna da kayan haja. Idan akwai kayan haja, ana ba da su ga mai amfani azaman samfuri ko nuni. Mafi mahimmanci, ana ƙayyade iko da fasalulluka na kayan aikin walda ta hanyar shawarwari tare da mai amfani, kuma ya kamata mu samar wa mai amfani da samfurin kayan aiki mai tsada dangane da farashin siye. A cikin wane yanayi ne ya fi kyau a yi amfani da injin walƙiya na laser na hannu, idan aka kwatanta da injin walƙiya mai sarrafa kansa, ba kawai tsadar siyan ba ne, amma farashin kulawa yana da yawa sosai. Abinda ya fi dacewa shine mafi mahimmanci shine don kiyayewa kuma a dabi'ance mafi girman farashi. Bugu da kari, cikakken atomatik Laser waldi yafi mayar da hankali a kan CNC aiki da kai na aikin dandali, wanda na bukatar high ayyuka da kuma versatility na aikin dandali, amma a yi, wannan ba panacea, da yawa sauya daban-daban kayayyakin ba za a iya amfani da, wanda. iyakance rawar atomatik Laser waldi inji. A yau, muna mai da hankali kan injin walda laser na hannu, don haka na'urar ta hanyar dabi'a tana warware matsalolin da ke sama. Ayyukansa na walda shine yin aikin walda ta hanyar haɗin gwiwar walda na Laser na hannu tare da kusurwoyi daban-daban na sarrafawa, don haka ana iya cewa kayan aikin Laser ba na al'ada ba ne don dacewa da walda nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan iri. Muddin ƙarfin yana da girma, zai iya daidaitawa da walda na yawancin samfuran

Ingantattun injunan waldawa na laser na hannu yana da ƙasa da na kayan aikin da aka sarrafa gabaɗaya. Duk da haka, don sarrafawa da rarrabawa ko aiki mara girman girma da walƙiya na masana'antar samarwa, waldawar laser na hannu ya fi fa'ida. Babu buƙatar saita teburin walda kuma kauce wa matsalar babban filin bene. Bugu da ƙari, ƙananan tarurruka suna walda samfurori iri-iri tare da sifofi marasa daidaituwa, don haka waldawar laser na hannu zai iya cika bukatun irin wannan samarwa kuma yana da kyakkyawar daidaitawa.

Manual Laser waldi ba tare da daidaici waldi tebur, low amfani da consumables da low tabbatarwa farashin kayan aiki. Gabaɗaya magana, muna buƙatar kula da ƙarin benches, yayin da kayan aikin laser na hannu na iya kammala aikin muddin an sanye shi da haɗin gwiwar walƙiya mai ɗaukar hoto. Sauƙi don maye gurbin, ƙananan farashi na sassa masu sauyawa. Idan ba ku san yadda ake maye gurbinsu ba, kuna iya ba su ga masana'anta don kulawa kai tsaye ba tare da damuwa game da jigilar kaya ba.

Bambanci tsakanin injunan waldawa ta Laser na atomatik da na'urorin walda na laser na hannu an raba su anan. Mutane da yawa na iya tunanin cewa injin walƙiya mai sarrafa kansa ya fi kyau saboda yana aiki ta atomatik, amma gaskiyar ita ce ana amfani da nau'ikan kayan aiki guda biyu don dalilai daban-daban kuma kowanne yana da nasa amfanin. A cikin tsarin zaɓin, muna kuma buƙatar zaɓar kayan aikin walda na laser daidai don samar da mu bisa ga ainihin bukatunmu.

Lokacin aikawa: Fabrairu-01-2023