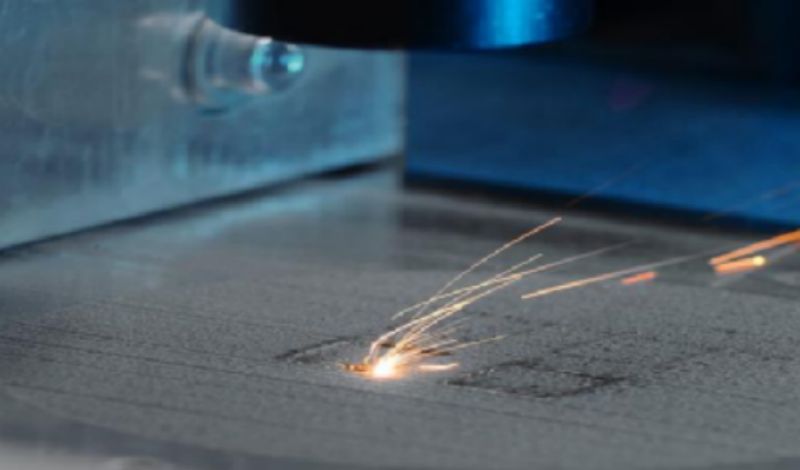

Laser walda

A cikin 'yan shekarun nan, godiya ga saurin bunƙasa sabon masana'antar makamashi, walƙiya ta Laser ya shiga cikin dukkan sabbin masana'antar makamashi cikin hanzari saboda fa'idodinsa cikin sauri da kwanciyar hankali.Daga cikin su, Laser walda kayan aiki lissafinsu ga mafi girma rabo na aikace-aikace a cikin dukan sabon makamashi masana'antu.

Walda Laser da sauri ya zama zaɓi na farko a kowane fanni na rayuwa saboda saurin saurin sa, zurfin zurfinsa, da ƙananan nakasawa.Daga tabo welds zuwa gindi walda, ginawa da hatimi waldi, Laser walda yana samar da daidaici da iko.Yana taka muhimmiyar rawa wajen samar da masana'antu da masana'antu, ciki har da masana'antun soja, kula da lafiya, sararin samaniya, 3C auto sassa, inji takardar karfe, sabon makamashi da sauran masana'antu.

Idan aka kwatanta da sauran fasahohin walda, waldar Laser yana da fa'ida da rashin amfaninsa na musamman.

Amfani:

1. Saurin sauri, babban zurfin da ƙananan nakasa.

2. Ana iya yin walda a zafin jiki na al'ada ko a ƙarƙashin yanayi na musamman, kuma kayan aikin walda yana da sauƙi.Misali, katakon Laser ba ya shawagi a cikin filin lantarki.Lasers na iya waldawa a cikin injin daskarewa, iska ko wasu mahalli na gas, kuma suna iya walda kayan da ke cikin gilashi ko bayyane zuwa katako na Laser.

3. Yana iya walda kayan refractory kamar titanium da ma'adini, kuma yana iya walda kayan da ba su da kama da sakamako mai kyau.

4. Bayan da aka mayar da hankali kan laser, ƙarfin ƙarfin yana da girma.Matsakaicin yanayin zai iya kaiwa 5:1, kuma yana iya kaiwa zuwa 10:1 lokacin walda na'urori masu ƙarfi.

5. Micro walda za a iya yi.Bayan an mai da hankali kan katako na Laser, ana iya samun ƙaramin tabo kuma ana iya sanya shi daidai.Yana za a iya amfani da taro da waldi na micro da kananan workpieces cimma sarrafa kansa taro samar.

6. Yana iya walda wuraren da ke da wuyar isarwa da yin walda mai nisa mara lamba, tare da sassauci sosai.Musamman a shekarun baya-bayan nan, fasahar sarrafa Laser ta YAG ta rungumi fasahar watsa fiber na gani, wanda ya ba da damar fasahar walda ta Laser ta samu ci gaba da amfani da ita.

7. Laser katako yana da sauƙi don raba lokaci da sarari, kuma ana iya sarrafa katako da yawa a wurare da yawa a lokaci guda, yana ba da yanayi don ƙarin walƙiya daidai.

Lalacewa:

1. Ana buƙatar daidaiton taro na aikin aikin ya zama babba, kuma matsayi na katako a kan aikin ba zai iya zama mai mahimmanci ba.Wannan saboda girman tabo Laser bayan mayar da hankali kadan ne kuma kabu mai kunkuntar, yana sa ya zama da wahala a ƙara kayan ƙarfe na filler.Idan taron daidaito na workpiece ko sakawa daidaito na katako bai dace da bukatun, waldi lahani ne yiwuwa ya faru.

2. Kudin lasers da tsarin da ke da alaƙa yana da girma, kuma zuba jari na lokaci ɗaya yana da yawa.

Lalacewar walƙiya gama gari a cikin masana'antar batirin lithium

1. Welding porosity

Lalacewar gama gari a waldawar Laser sune pores.Tafkin narkakkar walda yana da zurfi kuma kunkuntar.A lokacin aikin waldawar laser, nitrogen yana mamaye tafkin narkakkar daga waje.A lokacin sanyaya da ƙarfafa tsarin ƙarfe, ƙarancin nitrogen yana raguwa tare da rage yawan zafin jiki.Lokacin da narkakkar pool karfe sanyaya don fara crystallize, , da solubility zai sauke sharply kuma ba zato ba tsammani.A wannan lokacin, babban adadin iskar gas zai yi hazo don samar da kumfa.Idan gudun kumfa ya yi ƙasa da gudun kristal ɗin ƙarfe, za a haifar da pores.

A aikace-aikace a cikin masana'antar baturi na lithium, sau da yawa muna ganin cewa pores na iya faruwa musamman a lokacin walda na ingantacciyar lantarki, amma ba kasafai suke faruwa ba yayin waldawar wutar lantarki mara kyau.Wannan shi ne saboda tabbataccen lantarki da aka yi da aluminium kuma an yi shi da jan ƙarfe mara kyau.A lokacin walda, ruwa na aluminum da ke saman ya takure kafin iskar gas na cikin gida ya mamaye gaba daya, wanda hakan ya hana iskar gas ya cika da samar da manyan ramuka da kanana.Ƙananan stomata.

Bugu da ƙari, abubuwan da ke haifar da pores da aka ambata a sama, pores sun hada da iska a waje, danshi, man fetur, da dai sauransu. Bugu da ƙari, shugabanci da kusurwar busa nitrogen zai kuma shafi samuwar pores.

Amma yadda za a rage abin da ya faru na walda pores?

Na farko, kafin waldawa, tabon mai da ƙazanta a saman kayan da ke shigowa suna buƙatar tsaftace cikin lokaci;a cikin samar da batirin lithium, binciken kayan da ke shigowa shine muhimmin tsari.

Na biyu, ya kamata a daidaita kwararar iskar gas ɗin garkuwa bisa ga dalilai kamar saurin walda, ƙarfi, matsayi, da sauransu, kuma bai kamata ya yi girma ba ko ƙanƙanta.Ya kamata a daidaita matsa lamba na alkyabbar kariya bisa ga dalilai kamar ikon laser da matsayi na mayar da hankali, kuma bai kamata ya zama babba ko ƙasa ba.Ya kamata a daidaita siffar bututun alkyabba mai kariya bisa ga siffa, shugabanci da sauran abubuwan walda domin alkyabbar kariya ta iya rufe wurin walda daidai gwargwado.

Na uku, sarrafa zafin jiki, zafi da ƙura a cikin iska a cikin bitar.Yanayin zafin jiki da zafi zai shafi abubuwan da ke cikin damshin da ke saman ƙasa da iskar gas mai karewa, wanda hakan zai shafi tsarawa da tserewa tururin ruwa a cikin narkakken tafkin.Idan yanayin yanayin zafi da zafi ya yi yawa, za a sami danshi mai yawa a saman ƙasa da iskar gas mai karewa, yana haifar da yawan tururin ruwa, yana haifar da pores.Idan yanayin zafi da zafi na yanayi ya yi ƙasa sosai, za a sami ɗanɗano kaɗan a saman ƙasan da kuma a cikin iskar gas mai karewa, rage haɓakar tururin ruwa, ta haka zai rage pores;bari ingantattun ma'aikata su gano ƙimar ƙimar zafin jiki, zafi da ƙura a tashar walda.

Na hudu, ana amfani da hanyar jujjuyawar katako don rage ko kawar da pores a cikin walda mai zurfin shigar da leza.Saboda kari na lilo a lokacin walda, jujjuyawar katakon katako zuwa kabu na walda yana haifar da sake narkewar wani bangare na kabu na walda, wanda ke tsawaita lokacin zama na karfen ruwa a cikin tafkin walda.A lokaci guda, jujjuyawar katako kuma yana ƙara shigar da zafi a kowane yanki na yanki.An rage zurfin-da-nisa rabo na weld, wanda ke da tasiri ga fitowar kumfa, don haka yana kawar da pores.A daya bangaren kuma, jujjuyawar katakon yana haifar da dan karamin rami don yin murzawa daidai da haka, wanda kuma zai iya ba da karfin motsa jiki ga tafkin walda, da kara jujjuyawa da kuma motsa tafkin, kuma yana da tasiri mai amfani wajen kawar da pores.

Na biyar, mitar bugun bugun jini, mitar bugun bugun jini tana nufin adadin bugun jini da na'urar Laser ke fitarwa a kowane lokaci naúrar, wanda zai shafi shigar da zafi da tara zafi a cikin narkakken tafkin, sannan ya shafi filin zafin jiki da filin kwarara a cikin narkakkar. tafkinIdan mitar bugun bugun jini ya yi yawa, zai haifar da shigar da zafi mai yawa a cikin tafkin narkakkar, wanda zai haifar da yanayin zafi na narkakkar, yana haifar da tururin ƙarfe ko wasu abubuwan da ke da ƙarfi a yanayin zafi, wanda ke haifar da pores.Idan mitar bugun jini ya yi ƙasa sosai, zai haifar da rashin isasshen zafi a cikin ruwan narkakkar, wanda zai haifar da yanayin zafi na narkakkar tafkin ya yi ƙasa da ƙasa, yana rage narkar da iskar gas, wanda ke haifar da pores.Gabaɗaya magana, ya kamata a zaɓi mitar bugun bugun jini a cikin kewayo mai ma'ana dangane da kauri da ƙarfin Laser, kuma a guji zama babba ko ƙasa da ƙasa.

Ramin walda (Laser waldi)

2. Weld spatter

Wutar da aka samar yayin aikin walda, waldar Laser zai yi tasiri sosai ga ingancin walda, kuma zai gurɓata da lalata ruwan tabarau.A general yi shi ne kamar haka: bayan Laser waldi da aka kammala, da yawa karfe barbashi bayyana a saman na kayan ko workpiece da kuma manne da surface na kayan ko workpiece.Mafi kyawun aikin shine cewa lokacin walda a cikin yanayin galvanometer, bayan tsawon lokacin amfani da ruwan tabarau na galvanometer, za a sami ramuka masu yawa a saman, kuma waɗannan ramukan suna faruwa ta hanyar waldawa.Bayan lokaci mai tsawo, yana da sauƙi a toshe hasken, kuma za a sami matsala ta hasken walda, wanda zai haifar da matsaloli masu yawa kamar walda da walƙiya.

Menene dalilan fantsama?

Na farko, ƙarfin wutar lantarki, mafi girman ƙarfin wutar lantarki, mafi sauƙi shine samar da spatter, kuma spatter yana da alaƙa kai tsaye da ƙarfin wutar lantarki.Wannan matsala ce ta karni.A kalla ya zuwa yanzu, masana’antar ta kasa magance matsalar fantsama, sai dai kawai za a iya cewa an dan rage ta.A cikin masana'antar batirin lithium, fantsama shine babban laifi na gajeriyar da'irar baturi, amma ya kasa magance tushen.Za'a iya rage tasirin spatter akan baturi kawai daga ma'anar kariya.Misali, ana ƙara da'irar tashoshin cire ƙura da murfin kariya a kusa da ɓangaren walda, kuma ana ƙara layuka na wuƙaƙen iska a cikin da'ira don hana tasirin spatter ko ma lalata baturi.Lalacewar muhalli, kayayyaki da abubuwan da ke kewaye da tashar walda za a iya cewa sun ƙare hanyoyin.

Game da magance matsalar spatter, kawai za a iya cewa rage ƙarfin walda yana taimakawa wajen rage spatter.Rage saurin walda shima zai iya taimakawa idan shigar bai isa ba.Amma a wasu buƙatun tsari na musamman, yana da ɗan tasiri.Tsarin iri ɗaya ne, injina daban-daban da batches na kayan daban-daban suna da tasirin walda daban-daban.Sabili da haka, akwai ƙa'idar da ba a rubuta ba a cikin sabon masana'antar makamashi, saiti ɗaya na sigogin walda don yanki ɗaya na kayan aiki.

Na biyu, idan ba a tsaftace saman kayan da aka sarrafa ko kayan aikin ba, tabon mai ko gurɓataccen mai zai haifar da fashe mai tsanani.A wannan lokacin, abu mafi sauƙi shine tsaftace farfajiyar kayan da aka sarrafa.

3. High reflectivity na Laser waldi

Gabaɗaya magana, babban tunani yana nufin gaskiyar cewa kayan sarrafawa yana da ɗan ƙaramin ƙarfi, ƙasa mai santsi, da ƙarancin sha don laser na kusa-infrared, wanda ke haifar da yawan iska mai yawa, kuma saboda ana amfani da mafi yawan lasers. a tsaye Saboda kayan abu ko ƙananan ƙima, hasken Laser mai dawowa ya sake shiga cikin fitar da kai, kuma ko da wani ɓangare na hasken dawowa yana haɗuwa a cikin fiber mai watsa makamashi, kuma ana watsa shi tare da fiber zuwa ciki. na Laser, sa core sassa a cikin Laser ci gaba da kasancewa a high zafin jiki.

Lokacin da reflectivity ya yi yawa a lokacin Laser waldi, da wadannan mafita za a iya dauka:

3.1 Yi amfani da murfin anti-tunani ko bi da saman kayan: shafa saman kayan walda tare da abin da ya dace na iya rage tasirin laser.Wannan shafi yawanci kayan aikin gani ne na musamman tare da ƙarancin haske wanda ke ɗaukar makamashin Laser maimakon nuna shi baya.A wasu matakai, kamar walda mai tarawa na yanzu, haɗi mai laushi, da sauransu, ana iya shigar da saman.

3.2 Daidaita kusurwar walda: Ta hanyar daidaita kusurwar walda, katako na laser na iya zama abin da ya faru a kan kayan walda a wani kusurwar da ya dace kuma ya rage abin da ya faru na tunani.A al'ada, samun abin da ya faru na katako na Laser daidai gwargwado zuwa saman kayan da za a yi waldawa shine hanya mai kyau don rage tunani.

3.3 Ƙara ƙarin abin sha: Yayin aikin walda, ana ƙara wani adadin abin sha, kamar foda ko ruwa, a cikin walda.Wadannan absorbers sha Laser makamashi da kuma rage reflectivity.Ana buƙatar zaɓin abin sha mai dacewa dangane da takamaiman kayan walda da yanayin aikace-aikacen.A cikin masana'antar batirin lithium, wannan ba zai yuwu ba.

3.4 Yi amfani da fiber na gani don watsa laser: Idan zai yiwu, za a iya amfani da fiber na gani don watsa Laser zuwa matsayin walda don rage haskakawa.Filayen gani na gani na iya jagorantar katakon Laser zuwa wurin waldawa don gujewa fallasa kai tsaye zuwa saman kayan walda da rage faruwar tunani.

3.5 Daidaita sigogi na Laser: Ta hanyar daidaita ma'auni kamar wutar lantarki, tsayin daka, da diamita mai mahimmanci, ana iya sarrafa rarraba wutar lantarki kuma ana iya rage tunani.Ga wasu kayan da ke nunawa, rage ikon laser na iya zama hanya mai tasiri don rage tunani.

3.6 Yi amfani da mai raba katako: Mai raba katako na iya jagorantar wani ɓangare na makamashin Laser zuwa na'urar ɗaukar hoto, ta haka zai rage faruwar tunani.Na'urori masu rarraba katako yawanci sun ƙunshi abubuwan gani da masu ɗaukar hoto, kuma ta zaɓin abubuwan da suka dace da daidaita tsarin na'urar, ana iya samun ƙarancin haske.

4. Welding undercut

A cikin tsarin kera batirin lithium, wadanne matakai ne suka fi haifar da yankewa?Me yasa rashin yankewa ke faruwa?Mu tantance shi.

Undercut, kullum waldi albarkatun kasa ba a hade da juna, da rata ne ma babba ko tsagi ya bayyana, zurfin da nisa ne m girma fiye da 0.5mm, jimlar tsawon ne mafi girma fiye da 10% na weld tsawon, ko mafi girma fiye da tsarin samfurin daidaitaccen tsayin da aka nema.

A cikin duka lithium baturi masana'antu tsari, undercutting ne mafi kusantar faruwa, kuma shi ne kullum rarraba a cikin sealing pre-waldi da waldi na cylindrical cover farantin da sealing pre-welding da waldi na square aluminum harsashi murfin farantin.Babban dalilin shi ne cewa sealing cover farantin bukatar hada kai tare da harsashi zuwa Welding, da matching tsari tsakanin sealing cover farantin da harsashi ne yiwuwa ga wuce kima weld gibba, tsagi, rushewa, da dai sauransu, don haka shi ne musamman yiwuwa ga undercuts. .

To mene ne ke haddasa rashin yankewa?

Idan saurin walda ya yi sauri, ƙarfen ruwa a bayan ƙaramin rami mai nuni zuwa tsakiyar walda ba zai sami lokacin sake rarrabawa ba, yana haifar da ƙarfafawa da raguwa a ɓangarorin biyu na weld.A cikin ra'ayi na sama halin da ake ciki, muna bukatar mu inganta waldi sigogi.Don sanya shi a sauƙaƙe, ana maimaita gwaje-gwaje don tabbatar da sigogi daban-daban, kuma a ci gaba da yin DOE har sai an sami sigogin da suka dace.

2.Yawan gibin walda, tsagi, rugujewa, da dai sauransu na kayan walda zai rage yawan narkakkar da ke cika gibin, wanda hakan zai sa an samu raguwar sassa.Wannan tambaya ce ta kayan aiki da albarkatun ƙasa.Ko albarkatun albarkatun walda sun cika buƙatun kayan da ke shigowa na tsarinmu, ko daidaiton kayan aikin ya dace da buƙatun, da dai sauransu. Al'adar al'ada ita ce ta ci gaba da azabtarwa da doke masu kaya da masu kula da kayan aiki.

3. Idan makamashin ya ragu da sauri a ƙarshen waldawar Laser, ƙaramin rami na iya rushewa, yana haifar da raguwa a cikin gida.Daidaitaccen madaidaicin iko da sauri na iya hana samuwar ɓarna.Kamar yadda tsohuwar maganar ke tafiya, maimaita gwaje-gwaje, tabbatar da sigogi daban-daban, kuma ci gaba da DOE har sai kun sami madaidaitan sigogi.

5. Rushewar cibiyar walda

Idan saurin walda yana jinkirin, narkakken tafkin zai zama babba kuma ya fi fadi, yana kara adadin narkakkar karfe.Wannan na iya sa kiyaye tashin hankali na saman ƙasa da wahala.Lokacin da narkakken ƙarfen ya yi nauyi sosai, tsakiyar walda zai iya nutsewa ya yi tsomawa da rami.A wannan yanayin, ana buƙatar rage yawan kuzarin da ya dace don hana rushewar tafkin.

A wani yanayi kuma, gibin walda kawai ya haifar da rugujewa ba tare da haifar da hushi ba.Wannan babu shakka matsala ce ta dacewa da buga kayan aiki.

Ingantacciyar fahimtar lahani da ka iya faruwa a lokacin waldawar Laser da kuma abubuwan da ke haifar da lahani daban-daban suna ba da damar ƙarin hanyar da aka yi niyya don warware duk wata matsala ta walda.

6. Weld fasa

Fatsin da ke fitowa yayin ci gaba da waldawar Laser galibi tsagewar zafi ne, irin su fashe-fashe na kristal da tsagewar ruwa.Babban abin da ke haifar da wannan tsaga shi ne manyan rundunonin rungumar da walda ke haifarwa kafin ya karye gaba daya.

Hakanan akwai dalilai masu zuwa na fasa waldi na Laser:

1. Ƙirar walda mara ma'ana: Rashin ƙira na lissafi da girman walda na iya haifar da damuwa na walda, ta haka yana haifar da fasa.Maganin shine don inganta ƙirar walda don guje wa damuwa walda.Kuna iya amfani da walda masu dacewa, canza siffar walda, da sauransu.

2. Rashin daidaituwar sigogin walda: Rashin zaɓi na sigogi na walda, kamar saurin walda, da ƙarfi da yawa, da sauransu, na iya haifar da canjin yanayin zafi mara daidaituwa a cikin yankin walda, yana haifar da babban damuwa na walda da fasa.Maganin shine daidaita sigogin walda don dacewa da takamaiman kayan aiki da yanayin walda.

3. Rashin shiri na shimfidar walda: Rashin tsaftacewa da kyau da kuma tuntuɓar farfajiyar walda kafin waldawa, kamar cire oxides, maiko, da sauransu, zai shafi inganci da ƙarfin walda kuma cikin sauƙi yana haifar da fasa.Magani shine a tsaftace da kyau da kuma tuntuɓar farfajiyar walda don tabbatar da cewa ƙazanta da gurɓataccen abu a cikin yankin waldawa an yi amfani da su yadda ya kamata.

. .Maganin shine don sarrafa zafin jiki da yanayin sanyaya yayin walda don guje wa zafi da saurin sanyi.

5. Rashin isassun taimako na damuwa: Rashin isasshen maganin damuwa bayan waldawa zai haifar da rashin isasshen damuwa a wurin da aka walda, wanda zai iya haifar da tsagewa cikin sauƙi.Maganin shine a yi maganin jinyar damuwa mai dacewa bayan waldawa, kamar maganin zafi ko jiyya (babban dalili).

Dangane da tsarin kera batirin lithium, wadanne matakai ne suka fi haifar da fasa?

Kullum, fasa ne yiwuwa faruwa a lokacin sealing waldi, kamar sealing waldi na cylindrical karfe bawo ko aluminum bawo, sealing waldi na square aluminum bawo, da dai sauransu Bugu da kari, a lokacin module marufi tsari, da waldi na yanzu mai tarawa ne kuma m. zuwa fasa.

Tabbas, zamu iya amfani da waya mai filler, preheating ko wasu hanyoyi don rage ko kawar da waɗannan fasa.

Lokacin aikawa: Satumba-01-2023