A cikin 'yan shekarun nan, Laser tsaftacewa ya zama daya daga cikin bincike hotspots a fagen masana'antu masana'antu, bincike maida hankali ne akan tsari, ka'idar, kayan aiki da kuma aikace-aikace. A cikin aikace-aikacen masana'antu, fasahar tsaftacewa ta Laser ta sami damar dogaro da tsabtace babban adadin sassa daban-daban, abubuwan tsaftacewa gami da ƙarfe, aluminum, titanium, gilashin da kayan haɗin gwiwa, da sauransu, masana'antar aikace-aikacen da ke rufe sararin samaniya, jirgin sama, jigilar kaya, babban sauri. jirgin kasa, mota, mold, makamashin nukiliya da ruwa da sauran filayen.

Fasaha mai tsaftace Laser, tun daga shekarun 1960, yana da fa'idodin tsaftacewa mai kyau, aikace-aikacen da yawa, babban madaidaici, rashin sadarwa da samun dama. A cikin masana'antun masana'antu, samarwa da kiyayewa da sauran fagage suna da fa'idodin aikace-aikace iri-iri, ana sa ran za su maye gurbin wani bangare ko gaba ɗaya hanyoyin tsaftacewa na gargajiya, kuma su zama mafi kyawun fasahar tsabtace kore a cikin ƙarni na 21st.

Hanyar tsaftace Laser

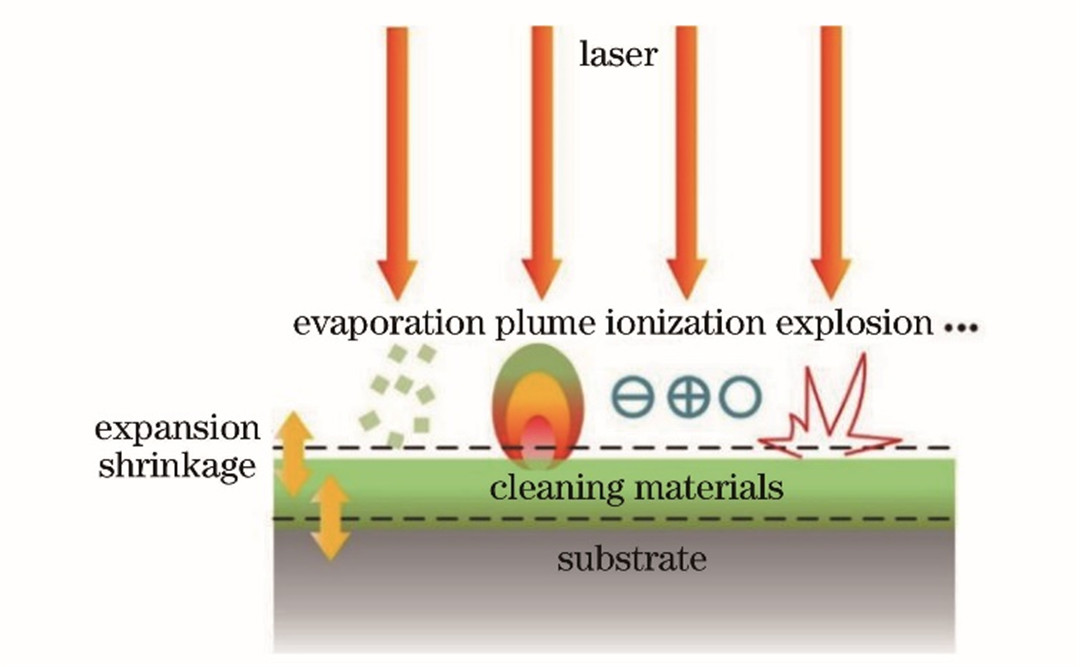

Tsarin tsaftacewa na Laser yana da matukar rikitarwa, ya ƙunshi nau'ikan hanyoyin cire kayan abu, don hanyar tsaftacewa ta Laser, tsarin tsaftacewa na iya kasancewa a lokaci guda nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan sun haɗa da, gami da ma'amala tsakanin Laser da kayan. da abu surface ablation, bazuwar, ionization, lalacewa, narkewa, konewa, vaporization, vibration, sputtering, fadada, shrinkage, fashewa, peeling, zubar da sauran jiki da kuma sinadaran canje-canje. tsari.

A halin yanzu, da hankula Laser tsaftacewa hanyoyin ne yafi uku: Laser ablation tsaftacewa, ruwa fim-taimaka Laser tsaftacewa da Laser girgiza kalaman tsaftacewa hanyoyin.

Hanyar tsaftacewar cirewar Laser

Babban hanyoyin da ake amfani da su sune haɓakar thermal, vaporization, ablation da fashewar lokaci. Laser yana aiki kai tsaye akan kayan da za'a cire daga saman ƙasa kuma yanayin yanayi na iya zama iska, iskar gas mai ƙarancin ƙarfi ko injin. Yanayin aiki yana da sauƙi kuma an fi amfani dashi don cire nau'i-nau'i iri-iri, fenti, barbashi ko datti. Hoton da ke ƙasa yana nuna zane-zane na tsari don hanyar tsaftacewa na laser.

Lokacin da hasken wuta na Laser a saman kayan abu, kayan aiki da kayan tsaftacewa sune farkon haɓakawar thermal. Tare da karuwa a lokacin hulɗar Laser tare da kayan tsaftacewa, idan zafin jiki ya kasance ƙasa da ƙaƙƙarfan ƙa'idar cavitation na kayan tsaftacewa, kayan tsaftacewa kawai tsarin canjin jiki, bambanci tsakanin kayan tsaftacewa da haɓakaccen haɓakawar thermal na substrate yana haifar da matsa lamba a cikin dubawa. , kayan tsaftacewa na buckling, tsagewa daga saman substrate, fashewa, fashewar inji, girgizar girgiza, da dai sauransu, an cire kayan tsaftacewa ta hanyar jet ko cirewa daga saman substrate.

Idan zafin jiki ya fi girma da zafin jiki na gasification na kayan tsaftacewa, za a sami yanayi guda biyu: 1) ƙaddamar da ƙaddamarwa na kayan tsaftacewa ya kasance ƙasa da substrate; 2) ƙofar ablation na kayan tsaftacewa ya fi girma.

Wadannan lokuta guda biyu na kayan tsaftacewa suna narkewa, cavitation da ablation da sauran sauye-sauye na physicochemical, tsarin tsaftacewa ya fi rikitarwa, ban da tasirin thermal, amma kuma yana iya haɗawa da kayan tsaftacewa da abubuwan da ke tsakanin sassan kwayoyin halitta, kayan tsaftacewa ko lalata, lokaci. fashewa, kayan tsaftacewa gasification nan take ionization, samar da plasma.

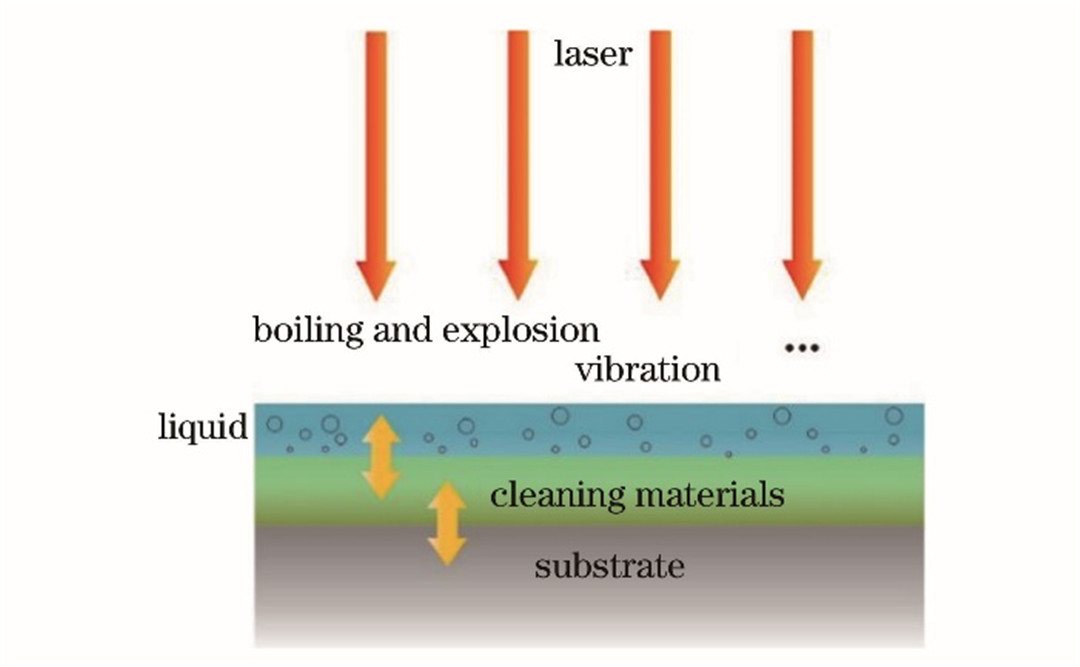

(1)Liquid fim taimaka Laser tsaftacewa

Hanyar inji yafi yana da ruwa film tafasar vaporization da vibration, da dai sauransu .. A amfani da bukatar zabi dace Laser kalaman, a hanyar da za a gyara ga rashin tasiri matsa lamba a cikin Laser ablation tsaftacewa tsari, za a iya amfani da su cire. wasu daga cikin mafi wahalar cire abin tsaftacewa.

Kamar yadda aka nuna a cikin hoton da ke ƙasa, fim ɗin ruwa (ruwa, ethanol ko wasu ruwaye) an riga an rufe shi a saman abin tsaftacewa, sa'an nan kuma amfani da Laser don haskaka shi. Liquid fim yana shayar da makamashin Laser wanda ke haifar da fashewa mai karfi na kafofin watsa labaru na ruwa, fashewar tafasar ruwa mai sauri mai sauri, canja wurin makamashi zuwa kayan tsaftacewa mai tsabta, babban fashewa mai fashewa ya isa ya cire datti na farfajiyar don cimma manufar tsaftacewa.

The ruwa fim-taimaka Laser tsaftacewa hanya yana da biyu disadvantages.

Tsari mai wahala da wahala don sarrafa tsarin.

Saboda yin amfani da fim din ruwa, nau'in sinadarai na substrate surface bayan tsaftacewa yana da sauƙin canzawa da samar da sababbin abubuwa.

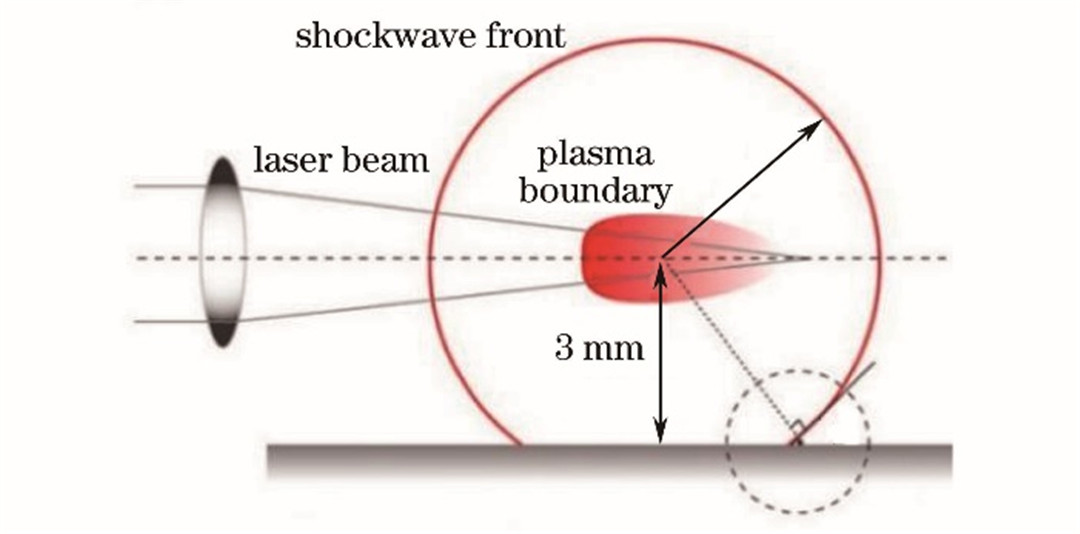

(1)Hanyar tsabtace nau'in girgiza Laser

Tsari tsarin da inji ne sosai daban-daban daga na farko biyu, da inji ne yafi girgiza kalaman karfi kau, tsaftacewa abubuwa ne yafi barbashi, yafi domin kau da barbashi (sub-micron ko nanoscale). Abubuwan da ake buƙata na tsari suna da tsauri, duka don tabbatar da cewa ikon ionize iska, amma kuma don kula da nisa mai dacewa tsakanin Laser da substrate don tabbatar da cewa aikin akan barbashi na tasirin tasirin ya isa.

Laser girgiza kalaman tsaftacewa tsari zane aka nuna a kasa, da Laser zuwa layi daya da shugabanci na substrate surface harbi, da substrate ba ya zo cikin lamba. Matsar da workpiece ko Laser shugaban don daidaita Laser mayar da hankali ga barbashi kusa da Laser fitarwa, da mai da hankali batu na iska ionization sabon abu zai faru, sakamakon girgiza taguwar ruwa, girgiza taguwar ruwa zuwa m fadada na siffar zobe, da kuma mika zuwa lamba. tare da barbashi. Lokacin da lokacin juzu'i na jujjuyawar girgiza akan barbashi ya fi lokacin sashin tsayin daka da ƙarfin mannewa barbashi, za a cire barbashi ta hanyar mirgina.

Fasahar tsaftace Laser

Laser tsaftacewa inji ne yafi dogara ne a kan surface na abu bayan sha na Laser makamashi, ko vaporization da volatilization, ko nan take thermal fadada don shawo kan adsorption na barbashi a kan surface, sabõda haka, abu daga surface, sa'an nan a cimma manufar tsaftacewa.

Kusan taƙaitawa kamar: 1. Laser tururi bazuwar, 2. Laser tsiri, 3. thermal fadada datti barbashi, 4. substrate surface vibration da barbashi vibration hudu al'amura.

Idan aka kwatanta da na gargajiya tsaftacewa tsari, Laser tsaftacewa fasaha yana da wadannan halaye.

1. Tsabtace "bushe" ne, babu maganin tsaftacewa ko wasu hanyoyin magance sinadarai, kuma tsaftar ta fi aikin tsaftace sinadarai.

2. The ikon yinsa, daga cikin kau da datti da m substrate kewayon ne sosai fadi, da kuma

3. Ta hanyar tsari na Laser tsari sigogi, ba zai iya lalata da surface na substrate a kan tasiri kau da gurbatawa, shi ne surface a matsayin mai kyau a matsayin sabon.

4. Laser tsaftacewa za a iya sauƙi sarrafa kansa aiki.

5. Ana iya amfani da kayan aikin lalata Laser na dogon lokaci, ƙananan farashin aiki.

6. Laser tsaftacewa fasaha ne a: kore: tsaftacewa tsari, kawar da sharar gida ne m foda, kananan size, sauki don adanawa, m ba zai gurbata yanayi.

A cikin 1980s, saurin ci gaban masana'antar semiconductor a saman silin wafer mask gurɓataccen barbashi na fasahar tsaftacewa ya gabatar da buƙatu mafi girma, babban mahimmin abu shine shawo kan gurɓataccen ƙwayoyin ƙwayoyin cuta da substrate tsakanin babban ƙarfin adsorption. , Tsabtace sinadarai na gargajiya, tsaftacewa na inji, hanyoyin tsaftacewa na ultrasonic ba su iya biyan buƙatu ba, kuma tsaftacewar laser zai iya magance irin waɗannan matsalolin gurbatawa, bincike da aikace-aikace masu alaka da sauri sun haɓaka.

A cikin 1987, bayyanar farko na aikace-aikacen haƙƙin mallaka akan tsaftacewar Laser. A cikin 1990s, Zapka ya sami nasarar amfani da fasahar tsaftacewa ta Laser zuwa tsarin masana'antu na semiconductor don cire ƙananan barbashi daga saman abin rufe fuska, sanin farkon aikace-aikacen fasahar tsabtace laser a fagen masana'antu. 1995, masu bincike sun yi amfani da Laser 2 kW TEA-CO2 don samun nasarar cimma nasarar tsabtace fenti na jirgin sama.

Bayan shigar da 21st karni, tare da high-gudun ci gaba na matsananci-short bugun jini Laser, gida da kuma kasashen waje bincike da kuma aikace-aikace na Laser tsaftacewa fasaha hankali ya karu, mayar da hankali a kan surface na karfe kayan, hankula kasashen waje aikace-aikace ne jirgin sama fuselage Paint kau, mold. degenerasing surface, engine ciki carbon kau da surface tsaftacewa na gidajen abinci kafin waldi. US Edison Welding Institute Laser tsaftacewa na FG16 jirgin sama, lokacin da Laser ikon 1 kW, da tsaftacewa girma na 2.36 cm3 a minti daya.

Yana da kyau a faɗi cewa bincike da aikace-aikacen cire fenti na Laser na ci-gaba da sassa masu haɗawa shima babban wuri ne mai zafi. Sojojin ruwa na Amurka HG53, HG56 helikwafta propeller ruwan wutsiya da F16 jirgin saman jirgin saman lebur wutsiya da sauran hade saman an gane Laser fenti cire aikace-aikace, yayin da kasar Sin ta hada kayan a cikin jirgin sama aikace-aikace marigayi, don haka irin wannan bincike ne m a cikin komai.

Bugu da ƙari, yin amfani da fasahar tsaftacewa na Laser zuwa CFRP hadaddiyar giyar jiyya na haɗin gwiwa kafin gluing don inganta ƙarfin haɗin gwiwa kuma yana daya daga cikin binciken bincike na yanzu. daidaita Laser kamfanin zuwa Audi TT mota samar line don samar da fiber Laser tsaftacewa kayan aiki don tsaftace surface na hur aluminum gami kofa frame oxide fim. Rolls G Royce UK ya yi amfani da tsaftacewar Laser don tsaftace fim din oxide a saman kayan aikin injiniya na titanium.

Laser tsaftacewa fasaha ya ci gaba da sauri a cikin shekaru biyu da suka wuce, ko shi ne Laser tsaftacewa tsarin sigogi da kuma tsaftacewa inji, tsaftacewa abu bincike ko aikace-aikace na bincike ya sami babban ci gaba. Fasahar tsabtace Laser bayan bincike mai yawa na ka'idar, mayar da hankali kan bincikensa koyaushe yana karkata ne ga aikace-aikacen bincike, da kuma aiwatar da sakamako masu ban sha'awa. A nan gaba, fasahar tsaftace Laser a cikin kariyar abubuwan al'adu da ayyukan fasaha za a fi amfani da su sosai, kuma kasuwarta tana da faɗi sosai. Tare da ci gaban kimiyya da fasaha, aikace-aikacen fasahar tsaftacewa na Laser a cikin masana'antu yana zama gaskiya, kuma iyakar aikace-aikacen yana ƙara karuwa.

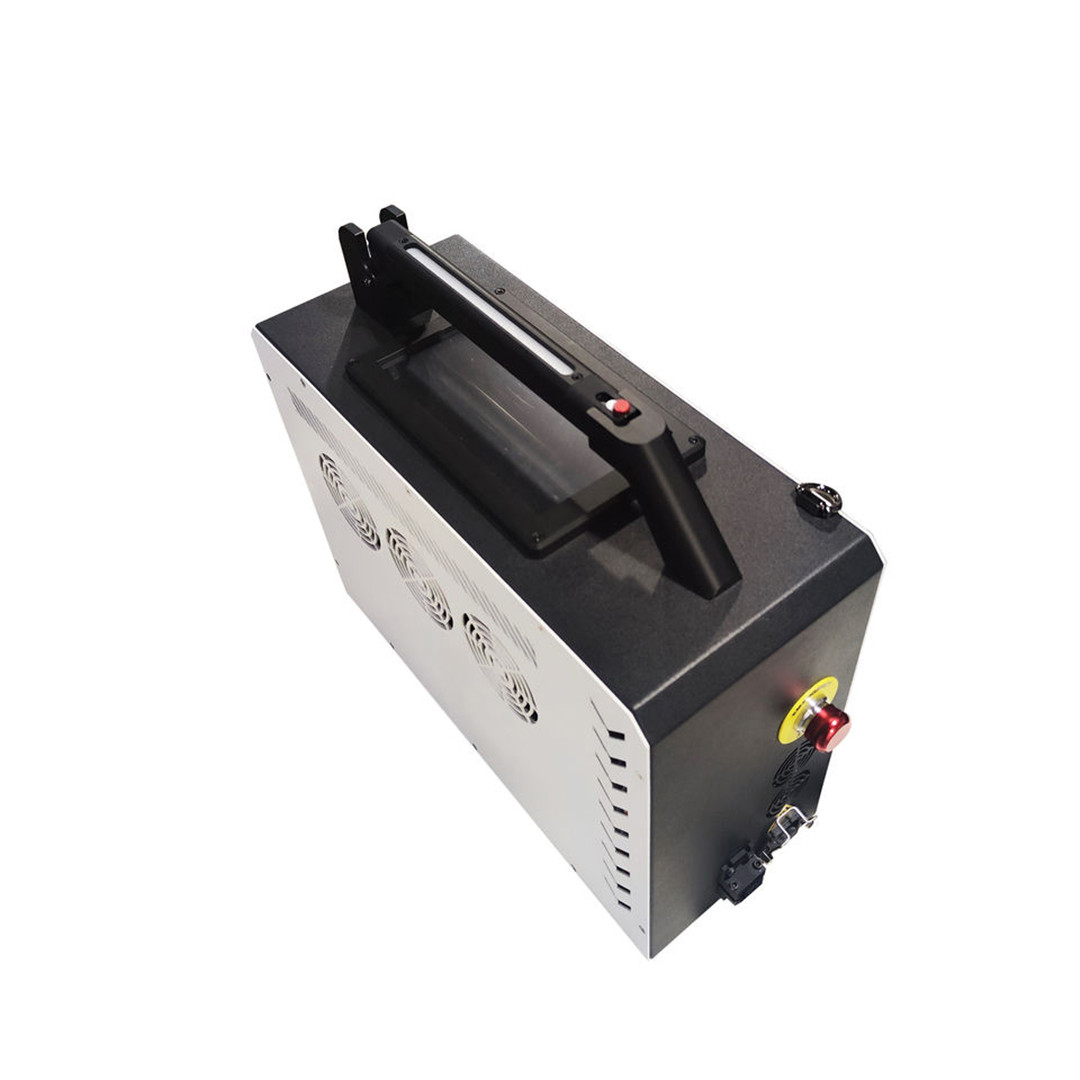

Maven Laser aiki da kai kamfanin mayar da hankali a kan Laser masana'antu for 14 shekaru, mu kware a Laser marking, muna da inji majalisar ministocin Laser tsaftacewa inji, trolley case Laser tsaftacewa inji, jakarka ta baya Laser tsaftacewa inji da uku a daya Laser tsaftacewa inji, a Bugu da kari, mu kuma da Laser waldi inji, Laser sabon na'ura da Laser alama engraving inji, idan kana sha'awar mu inji, za ka iya bi mu da kuma jin free to tuntube mu.

Lokacin aikawa: Nuwamba-14-2022